Outbound Process

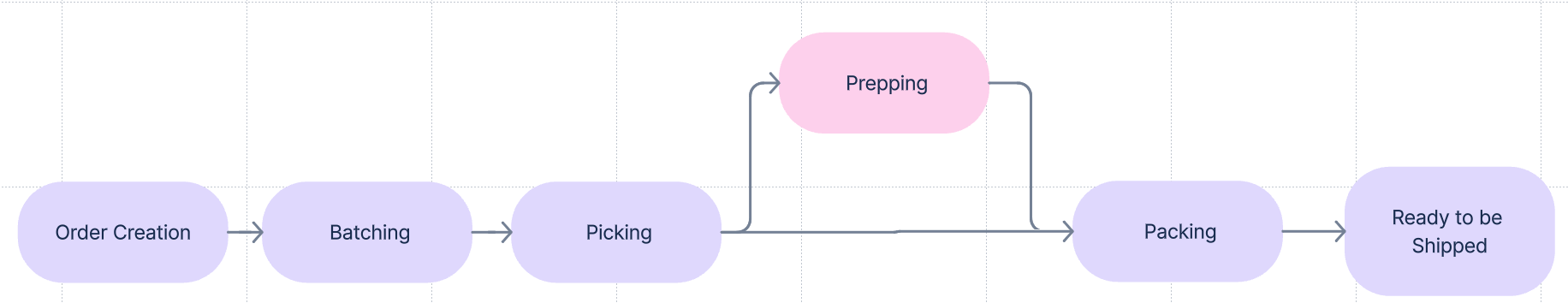

The outbound process starts with an outbound order (eg., sales order, stock transfer order). This order is then batched. Batching soft allocates inventory to the order and is followed by picking for the order. Prepping is an optional step required in specific cases eg., the product is to be sold through the Amazon marketplace. The next step is packing, once packed the shipping and box labels are generated and the product is ready to be shipped.

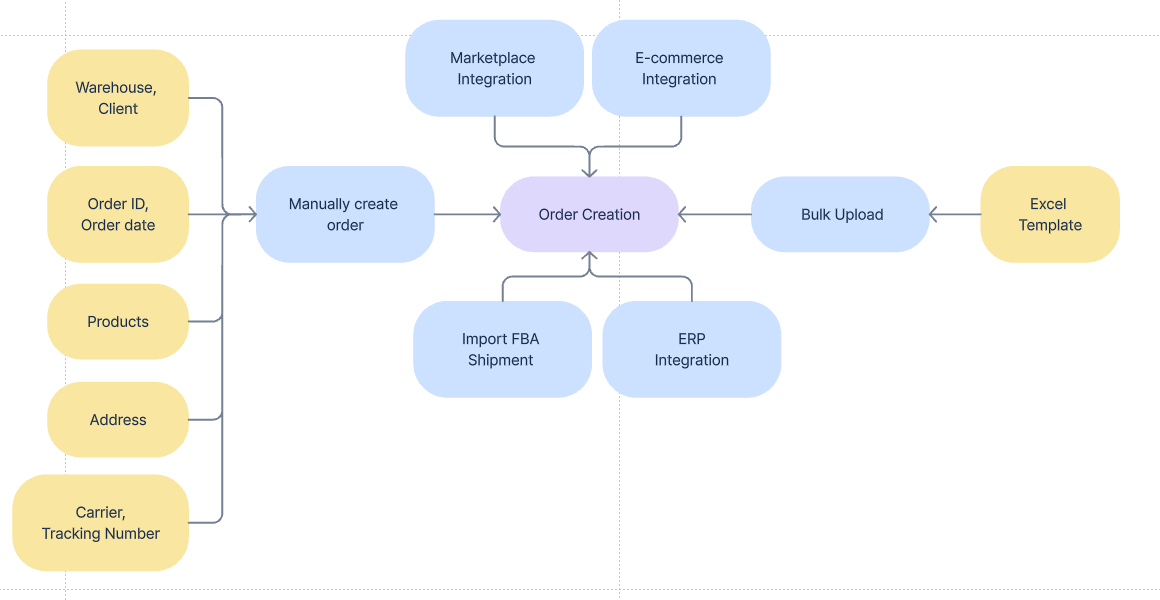

Order Creation Order Management - Creating an order

Outbound orders can be created in Hopstack manually as regular orders or through bulk upload. Orders could also come from various types of integrations through API or EDI.

The users can manage orders through the order management screen on Hopstack Order Management - Administrative View.

Filters can applied to this screen to create a custom view to view specific orders (eg., orders related to a particular client) Order Management Filters.

Users have the ability to perform actions such as editing order Editing an order , mark complete Marking an order complete , update carrier, view audit trail,Audit Trail for Outbound Orders , Download BOL, Download Pack list Download Pack List, mark complete in the marketplace - this action automatically updates the order as complete in the marketplace through API connections Marking an order complete in marketplace, edit shipment plan, manually update shipping information Manually updating shipping information , cancel shipment Cancelling a shipment and more based on the source of order.

The links mentioned below contain more information on the actions available.

a) Action Menu for Amazon Shipments

b) Action Menu for Hopstack Orders

Hopstack provides the user with an option to create a stock transfer order. Stock transfer is used in a multi-warehouse environment when there is a need to move inventory from one warehouse to anotherStock Transfer Orders.

A gated feature in Hopstack is rate shopping for shipment where the platform automatically receives shipping rates from a broad spectrum of carriers, including Amazon-partnered ones(if applicable) and users can choose the carrier that suits their needs September.

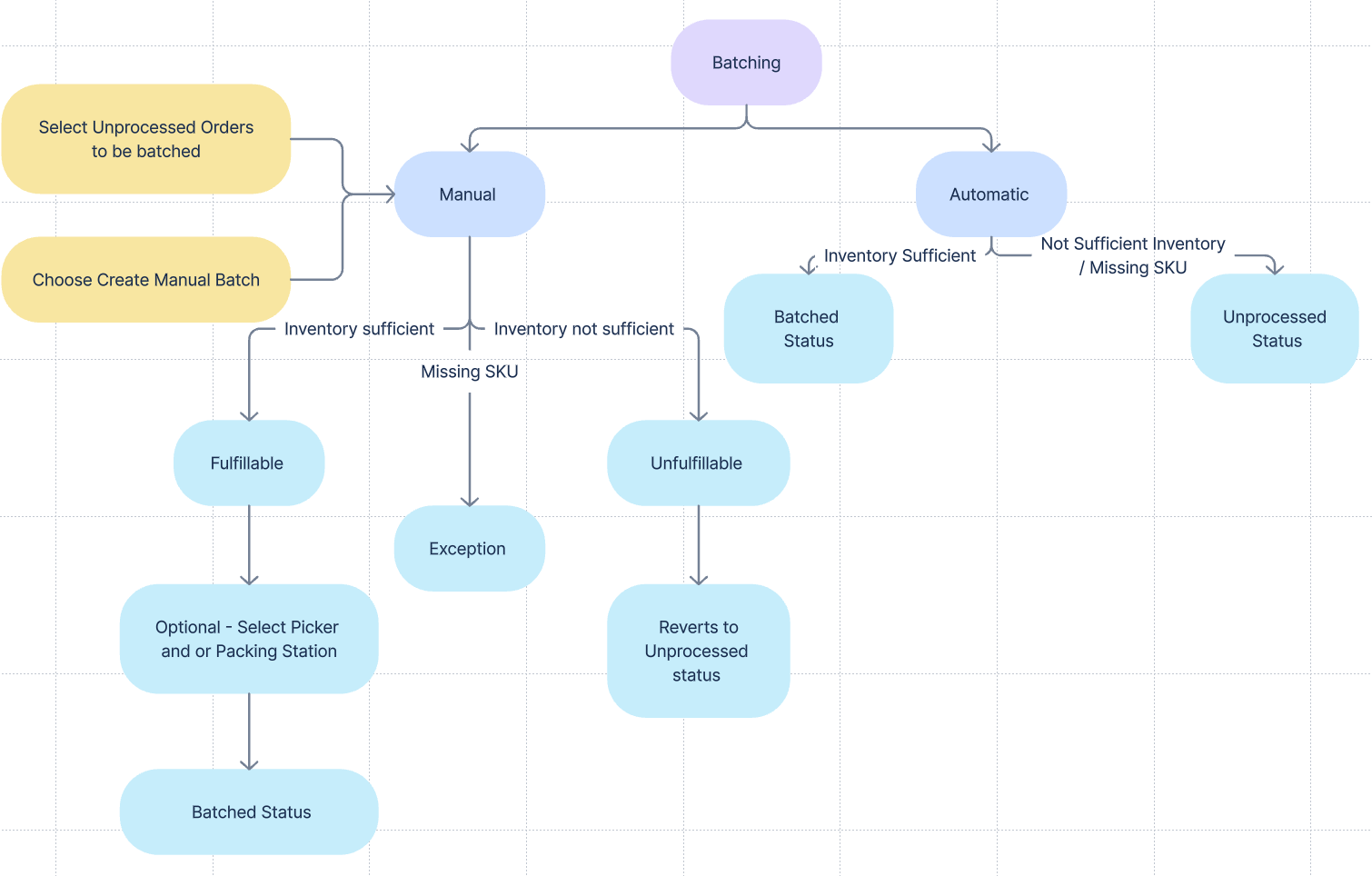

Batching

Hopstack gives users the option to batch the orders or automatically batch the orders manually. The above workflow shows the process flow for both Order Batching: Automatic and Manual.

During the creation of the order or while editing the unprocessed order, users have the option to add LPNs, Batch IDs/Lot IDs Adding Lot ID/Batch ID and LPNs to Orders and add the serial number Outbound Order Serialization.

Once batching is complete the order quantities get allocated to that order. The batched orders will be listed on the Outbound Operations summary page Summary Page. To unallocated the products the batch has to be deleted Deleting a Batch and Unallocating Orders/Products.

Hopstack has enabled batching and fulfilment when the inventory is available in different form factors to ensure that the higher form factor orders can be fulfilled using available lower form factor SKUs, reducing stock discrepancies and improving efficiencyFulfillment of Different UOMs While Batching Orders.

By enabling the multi-order operations and fulfilment feature, users can perform Multi-order batching Multi-Order Batching allowing efficient management and processing of multiple orders in a single batch, ensuring smooth and streamlined outbound logistics. Users are able to choose the batching strategy, set batch size limits, picking sequences in the settings to optimize the batching process Batch Settings.

A gated feature in Hopstack that can be enabled is the partial fulfilment option. Normally, if the inventory is insufficient to fulfil an order, the order remains in unprocessed status when batched. With this partial fulfilment feature enabled, the user will have the ability to fulfil partial orders in case of insufficient inventory and the unfulfillable part of the order becomes a backorder. Enable Partial Fulfilment

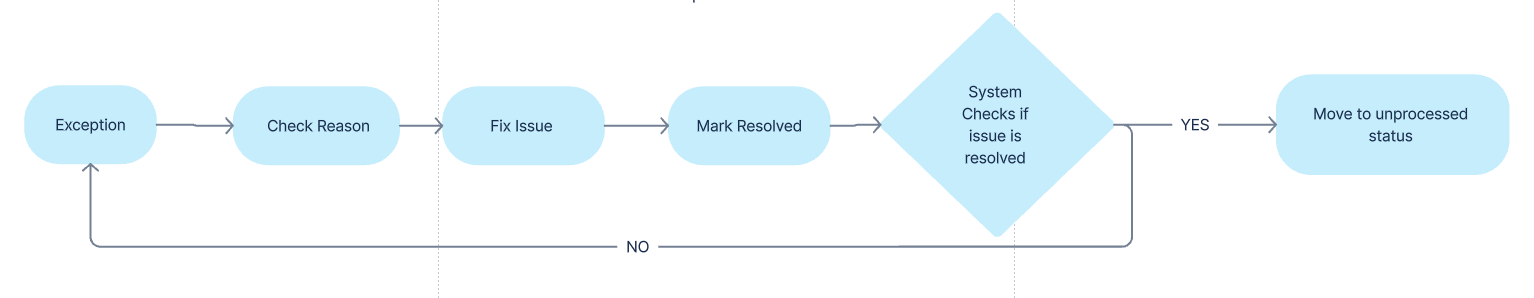

Exception

During the batching process, orders with missing product data move to exceptions. Users can check the reason for the exception Check Exception Reason and fix the issue. Once the issue is fixed, the user can mark the exception order as resolved. Hopstack also provides an option to bulk-resolve exceptions Bulk Resolve Exceptions.

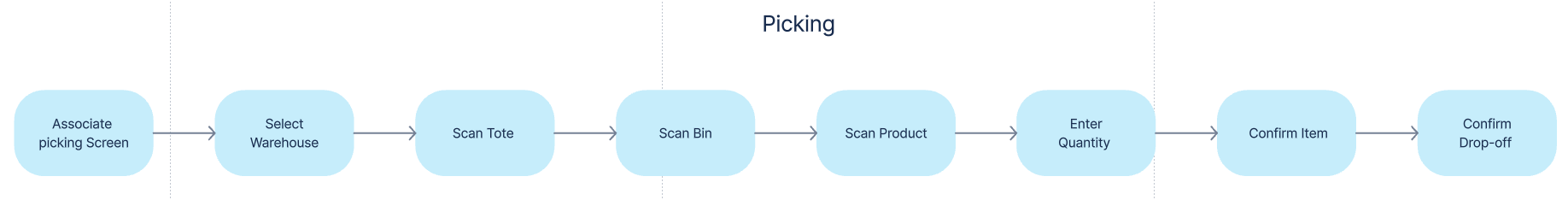

Picking Associate Workflow - Picking

Once the orders are batched, they are available for picking. The steps in picking are detailed below.

The associate logs in to start picking by choosing a warehouse and client and proceeds to get a new batch. Select Warehouse and Client to Get New Batch.

Scanning a tote is the next step in picking an order Scanning Order Tray.

Completion of this step brings you to the detailed view which displays details like the pick location, product and quantity for the first product in the order, there is also a list view which shows the summary of the order like products in the order, quantities required, quantities picked and status Views.

The actions are performed in the detailed view screen where the associate scans the location and item to confirm the picking of the items Scanning the Item and Confirming.

After the completion of picking Hopstack leads the associate to drop off the order at the next location which could be a prep station or a pack station depending on the defined outbound operations workflow Confirm Drop-off.

Hopstack provides the ability to prioritise a batch for picking Prioritise Batch. There is also the ability to reassign a new picker for an order when the original picker is unavailable or when there's a need to balance the workload among the team Reassign Picker.

Order status allows the user to track the progress of the process Order Status - Picking. Hopstack has enhanced picking strategies like FIFO, FEFO and Pallet Selection Algorithm—each plays a crucial role in enhancing space utilization, inventory turnover, and minimizing waste Enhanced Picking Strategies.

As part of the multi-order operations and fulfilment feature, users are able to perform multi-order picking after multi-order batching Multi-Order Picking. (Note: Multi-order picking is a mobile app-only feature)

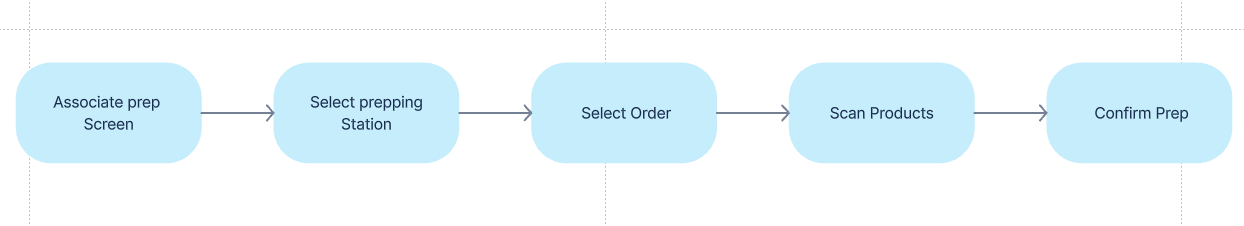

Prepping Associate Workflow - Prepping

This is an optional step that is relevant for prep-centres and for orders that require special prepping before packing.

Once the associate enters the prepping screen they select the prepping station and they can scan the tote or enter the order number to start prepping Scanning Orders, which is followed by scanning Scanning Products and confirming the items that have been prepped.

If there is an Amazon integration Amazon prep instructions appear in the scan product screen along with other product details Amazon Prep Instructions and there is also an option to add additional preparation requirements Additional Prep Type Dropdown.

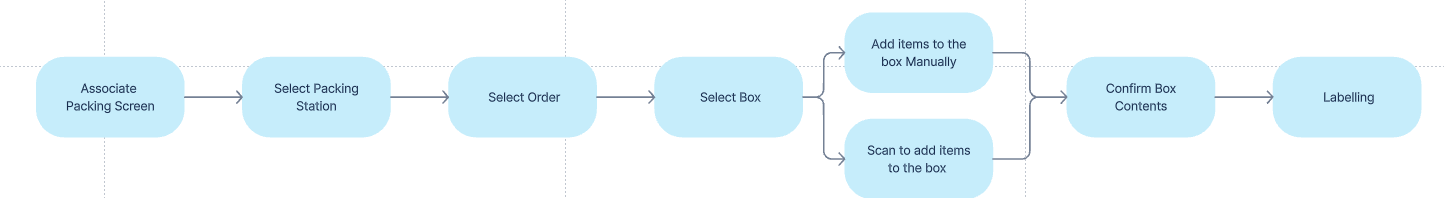

Packing Associate Workflow - Packing

The packing process steps are as follows.

The associate selects a packing station Selecting a Packing Station.

Once selected, the orders that were dropped off at that packing station are displayed in the orders screen from which the user can select an order to work on or in the scan view the order tray i.e., the tote can be scanned or the order ID can be manually entered to choose the orderSelecting an Order for Packing.

The packing screen has a List View showing the summary of products, quantities, and respective status and there is a detailed view screen for focusing on individual products and is used for performing actual packing Views on Packing Screen.

If the box feature is enabled, users are prompted to add a box by selecting the size Adding a Box after which the users can scan to add items to the box Scanning to Add Items to the Chosen Box or manually add items to the box Manually Adding Items to the Chosen Box.

Once the items are added to the box, the associate will confirm the box contents and enter the weight Confirming Box Contents. At the end of this step, shipping labels are generated based on the integration and/or the carriers chosen for the order. The box labels can be downloaded and re-printed if required Download or Print Box Labels. (Note: There is also an option to duplicate the box Duplicate Multiple Boxes. )

Hopstack provides an option to redo packing at the item level which helps correct packing errors at a granular level as opposed to re-packing the entire order Redo Packing (for individual items). The associates have the option to pause packing Pause Packing or restart packing Restart Packing (for entire orders) to handle unforeseen circumstances.

As part of the multi-order operations and fulfilment feature, users are able to perform multi-order packing to efficiently pack items for multiple orders in a single workflow Multi-Order Packing. (Note: Multi-order packing is a mobile app-only feature)

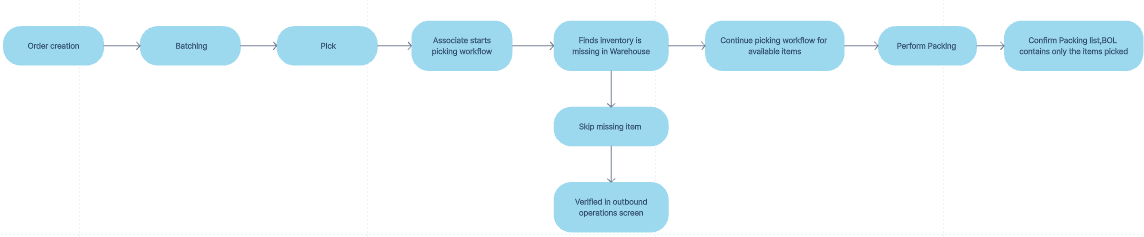

Partial Pick and Pack

The partial pick and pack is a feature that comes in handy when the inventory in the system doesn't match with the inventory physically present in the warehouse (i.e. when the system shows that inventory is available whereas the inventory in the warehouse is either missing or damaged). This feature allows the user to continue with the picking workflow and packing workflow by skipping the missing item.

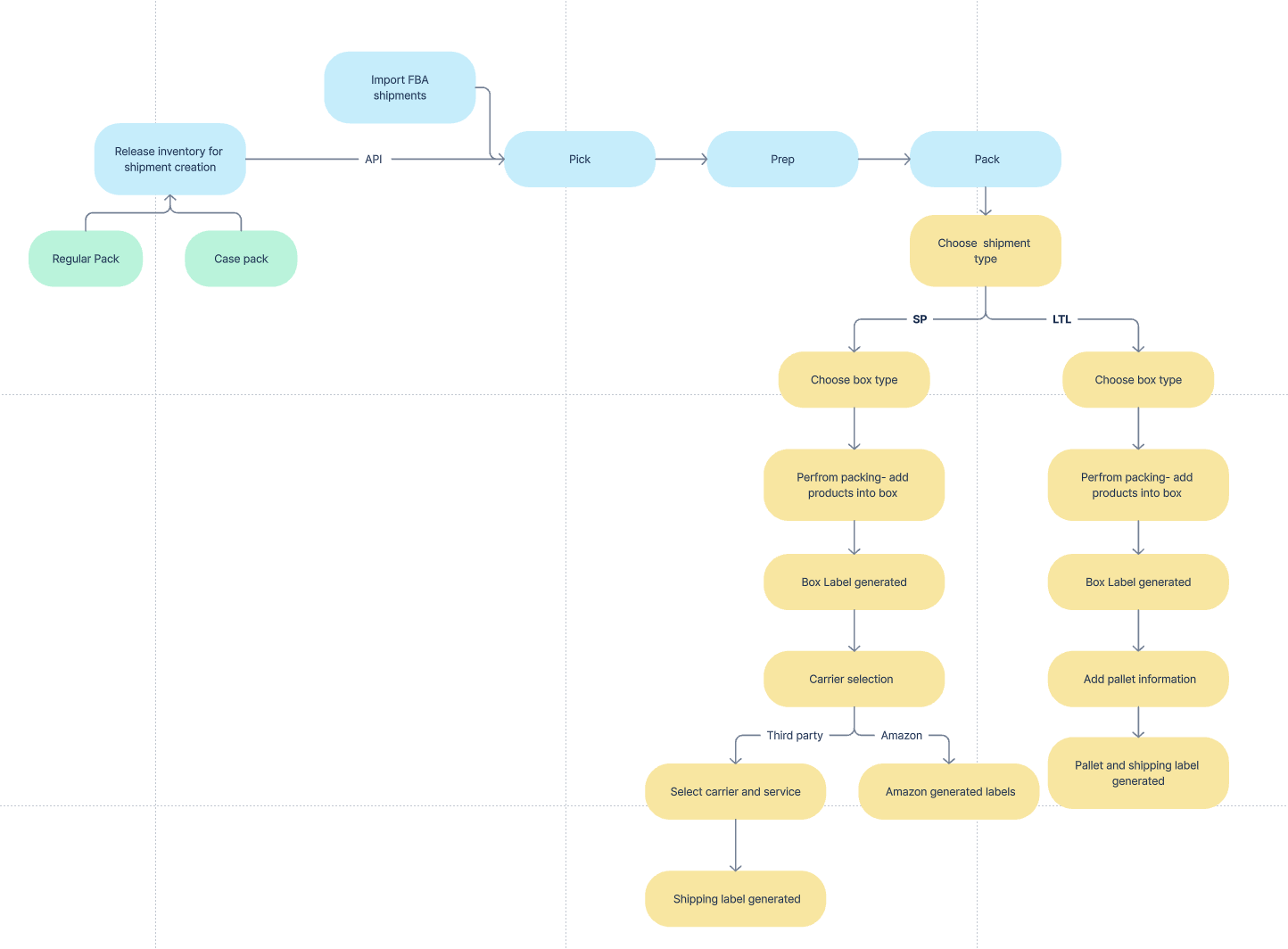

Multi-Pallet FBA LTL Workflow Multi-Pallet FBA LTL Workflow

FBA orders are generated either by releasing inventory for shipment creation or by importing FBA shipments into Hopstack Importing FBA Shipments.

The case pack shipment option in FBA provides the merchant with more control over the shipment Case Pack Shipments.

The picking and prepping process is similar to the process detailed in the previous sections.

The 2D barcode feature is enabled for Amazon FBA shipments to streamline the packing process and maintain compatibility with both partnered and non-partnered carriers 2D Barcodes for FBA shipments.

While the packing process remains predominantly similar, there are additional steps like adding pallet information for LTL orders and choosing the shipping method Rate Shopping For Less-Than-Truckload Shipments.

The shipping labels are generated based on the choices made. Hopstack provides a transparent view of each step involved in generating your shipment labels. Status Trail for Amazon Shipments.