Stock-Ledger

A stock ledger under Inventory logs all movements and adjustments of stock inside a warehouse.

It provides a complete, real-time view of all inventory and helps understand what's available.

Let's take a deeper look at each of the terms used in the stock ledger:

SKU (Stock Keeping Unit): A unique identifier for each different product in your inventory, making it easier to track its location, availability, and movements throughout the supply chain.

ASIN (Amazon Standard Identification Number): A unique block of 10 letters and/or numbers used to identify items on Amazon. Every product from Amazon is given a unique ASIN.

Name: The name or description of the product.

Consignments (Qty): The quantity of products expected in the next consignment or shipment. It helps in planning for the receipt of incoming goods.

Receiving Buffer (Qty): The total quantity of products currently received in the warehouse but not yet put away. This includes:

Qty at Docks

Qty in Inbound - Receiving

Qty in Inbound - Putaway

Qty in Inbound - X (X being all the other stations in the inbound workflow)

Storage (Qty):

The total quantity of products currently stored in the warehouse represents goods that have been received and put away but have not yet been dispatched in customer orders.

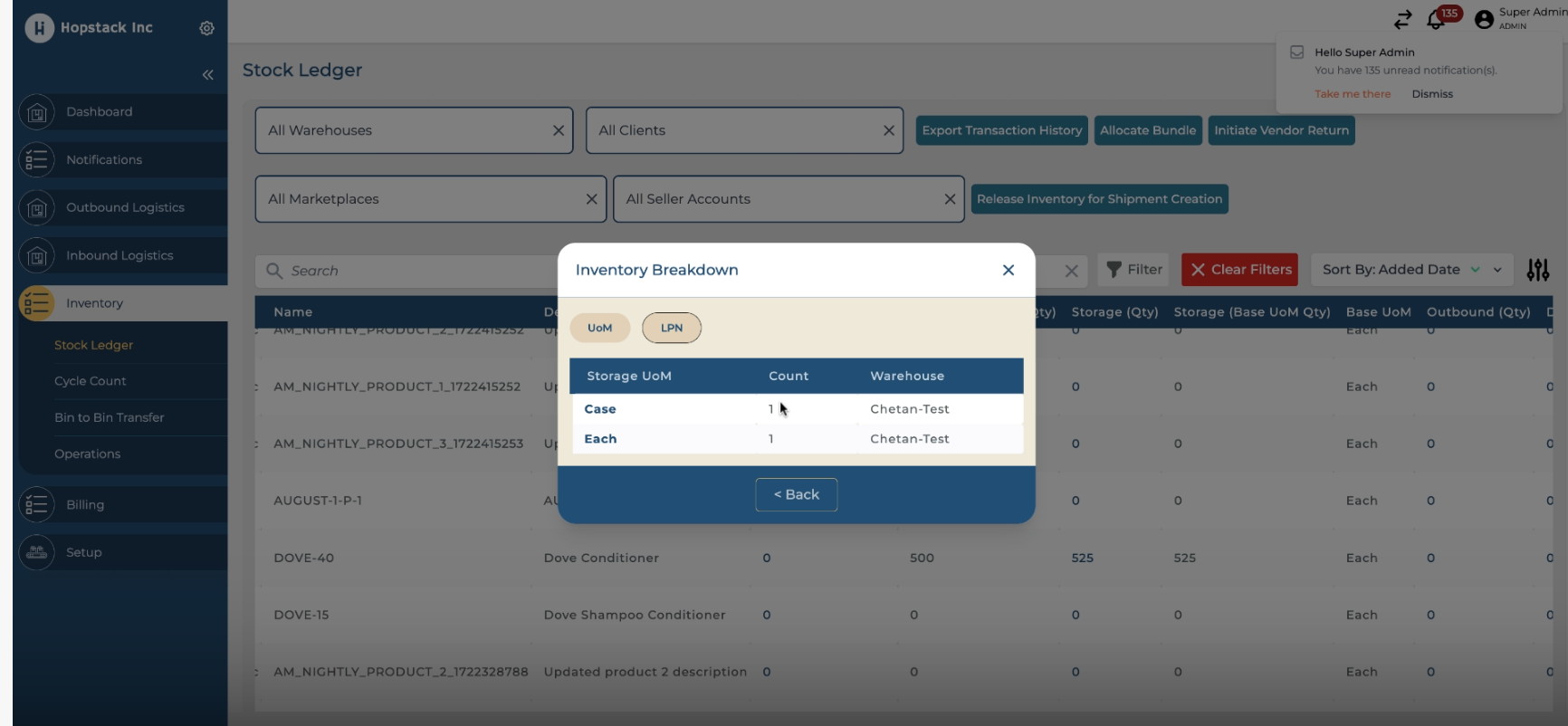

Clicking on the "Storage Qty" in the stock ledger view opens a modal window with a detailed breakdown of the inventory. This includes the following views:

UoM Breakdown:

UoM (Unit of Measure): The specific unit in which the product is measured (e.g., each, case, carton).

Available Qty: The quantity of the product currently available for use.

Allocated Qty: The quantity of the product that has been reserved or allocated for specific orders.

Warehouse: The specific warehouse location where the product is stored.

By clicking on any UoM (e.g., each, case, carton, etc.), users will be able to see a more granular view with additional details, including:

Location: The specific bin or area within the warehouse where the product is stored.

Available Qty: The exact quantity available at each specific location.

Allocated Qty: The quantity allocated at each specific location.

Tote: The identification number of the tote (if applicable) containing the product.

Expiry Date: The expiration date of the product, if applicable.

Lot/Batch ID: The identification number of the lot or batch the product belongs to.

Serial Number: The serial number of the product, if applicable.

LPN Breakdown:

This tab displays a table with the following columns:

Storage Unit

Count

Warehouse

Upon clicking the storage unit, users can view more detailed information, including:

Storage UoM

LPN (License Plate Number): The unique identifier for the pallet or container the product is stored in.

LPN Form Factor: The form factor of the LPN, indicating how the product is stored (e.g., pallet, carton).

Pallet ID: The identification number of the pallet containing the product.

Unallocated Qty: The quantity of the product not yet allocated to any order.

Allocated Qty: The quantity of the product reserved for specific orders.

SKU Location: The location where the SKU is stored.

This breakdown provides a comprehensive view of inventory, aiding in precise tracking and handling within the warehouse for better inventory management.

Storage in Base UoM:

Displays the quantity of products in storage converted to the base unit of measure (UoM).

Example: In this case, let us assume that the Base UoM is Each and 10 eaches = 1 carton and 5 cartons = 1 pallet. If there are 10 eaches and 2 cartons in storage, the Storage in Base UoM shows 30.

This column provides a clearer representation by converting all storage quantities to the base UoM of the product.

Outbound (Qty): The total quantity of products currently in the outbound process. The outbound process starts when items are picked from their storage locations for order fulfillment and ends when they are shipped to the customer. This includes:

Qty in Picking

Qty in Packing

Qty in Prepping

Qty in Outbound - X (X being all the other stations in the outbound workflow)

Damaged (Qty): The total quantity of products that have been damaged, resulting from various reasons such as poor handling, accidents, or defective items received from suppliers.

Total (Qty): The sum of the Inbound, Storage, Outbound, Damaged, and Unverified quantities.

Allocated: The total quantity of products that have been assigned or allocated to specific orders but have not yet been shipped out. These goods are effectively reserved and should not be considered available for new orders.

Available to Ship: The total quantity of products that are ready to be shipped out. This includes products that are currently in storage and not allocated to any order.

Marketplace (Qty): The quantity of products available for sale on a marketplace such as a web store or Amazon. It's crucial for this number to accurately reflect the actual inventory available to prevent overselling.

FnSKU: Fulfillment Network Stock Keeping Unit, a unique identifier used by Amazon to identify products stored and fulfilled by Amazon.

Source: The origin of the product, which could be the supplier or the specific location where the product was procured.

Base UoM (Unit of Measure): The standard unit of measure used for the product, ensuring consistency in tracking and reporting quantities.

Understanding and effectively managing your stock ledger helps maintain accurate inventory levels and ensure efficient order fulfillment. Use this guide as a tool to navigate inventory.