Split Order

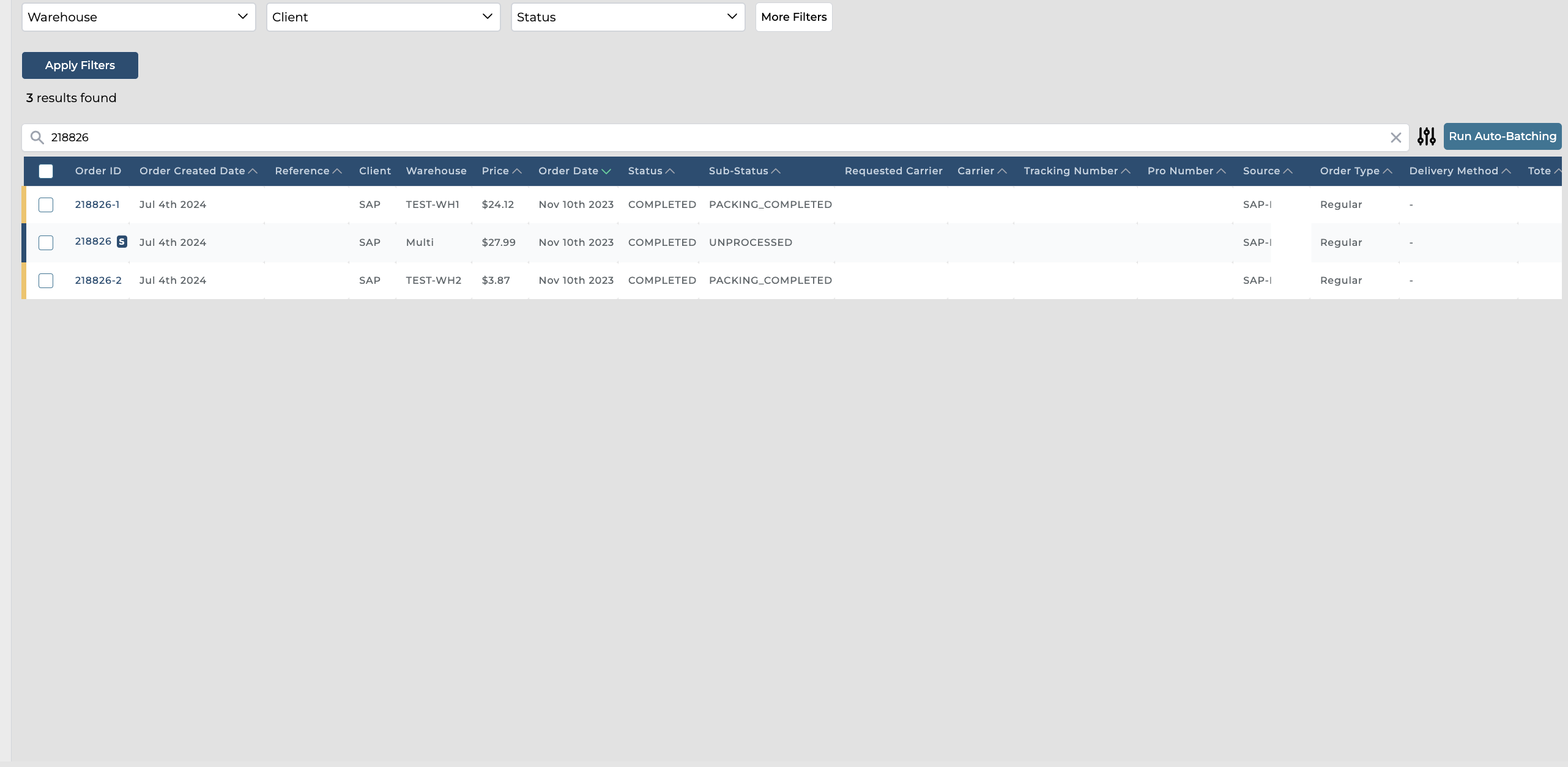

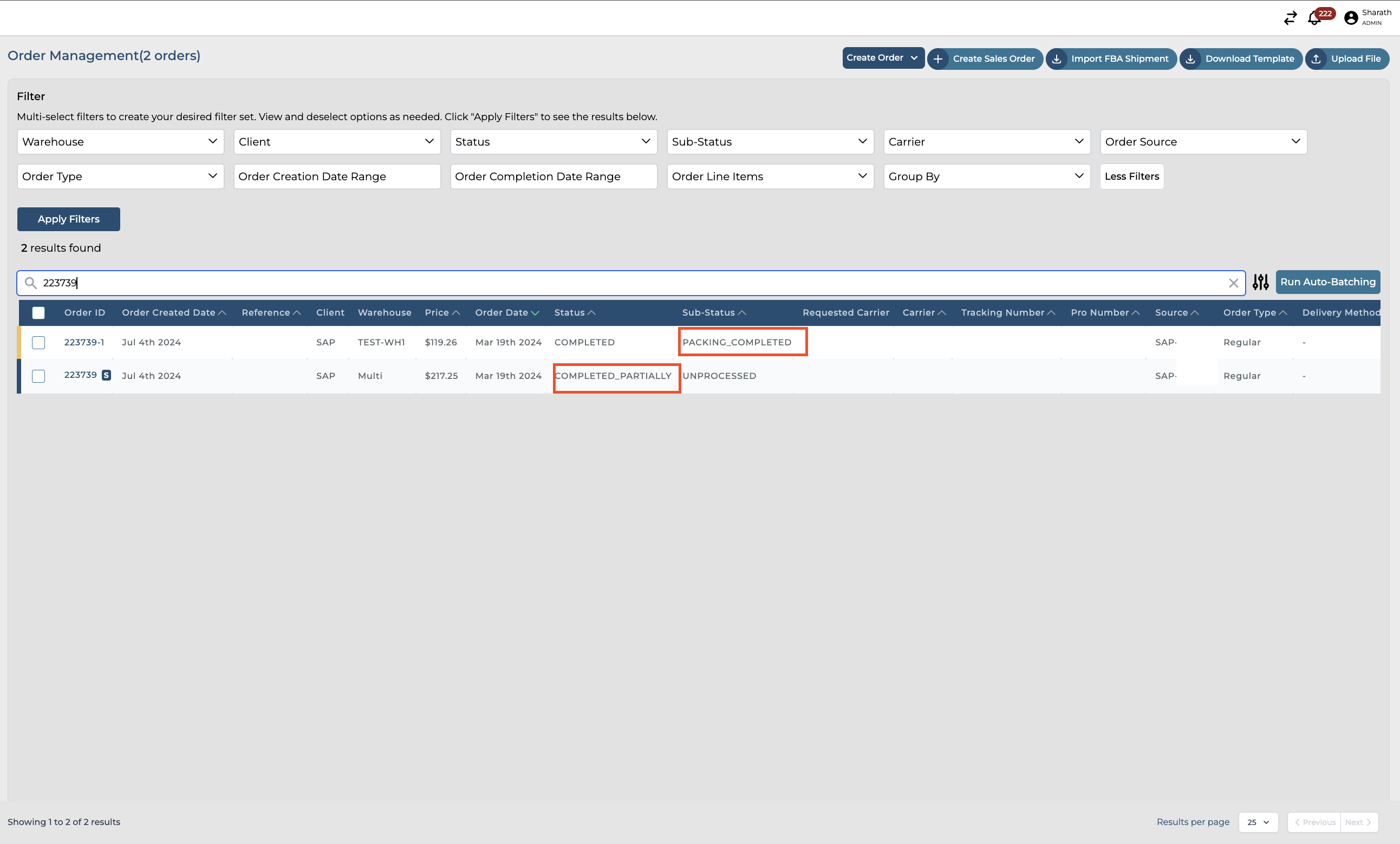

A split order is used in a multi-warehouse scenario when an order with multiple line items needs to be fulfilled from different warehouses. The parent order is split into two child orders based on the location of the warehouse by the ERP. The parent and child orders can be viewed on the order management screen in Hopstack as shown below.

Note: You cannot split an order on the Hopstack platform. The split orders are imported from the ERP system(Eg: SAP) where the warehouse is already defined.

Note: The Split order is a gated feature.

To know more about implementation, please contact your account manager.

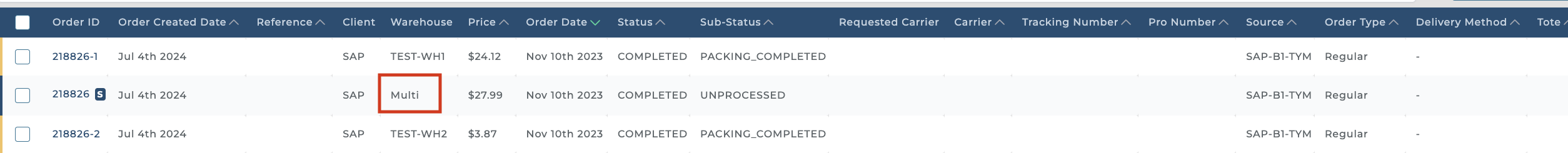

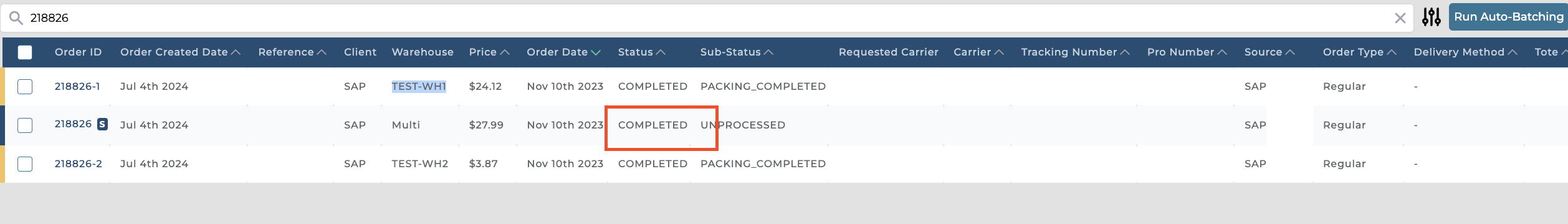

The parent order appears with S indicating that it is a split order - 218826 is the parent order.

The child orders are 218826-1 for the TEST-WH1 Location and TEST-WH2 Location.

If the order is split into two the user will see the Parent order warehouse as “Multi”, this indicates that the order has multiple line items allocated to different warehouses.

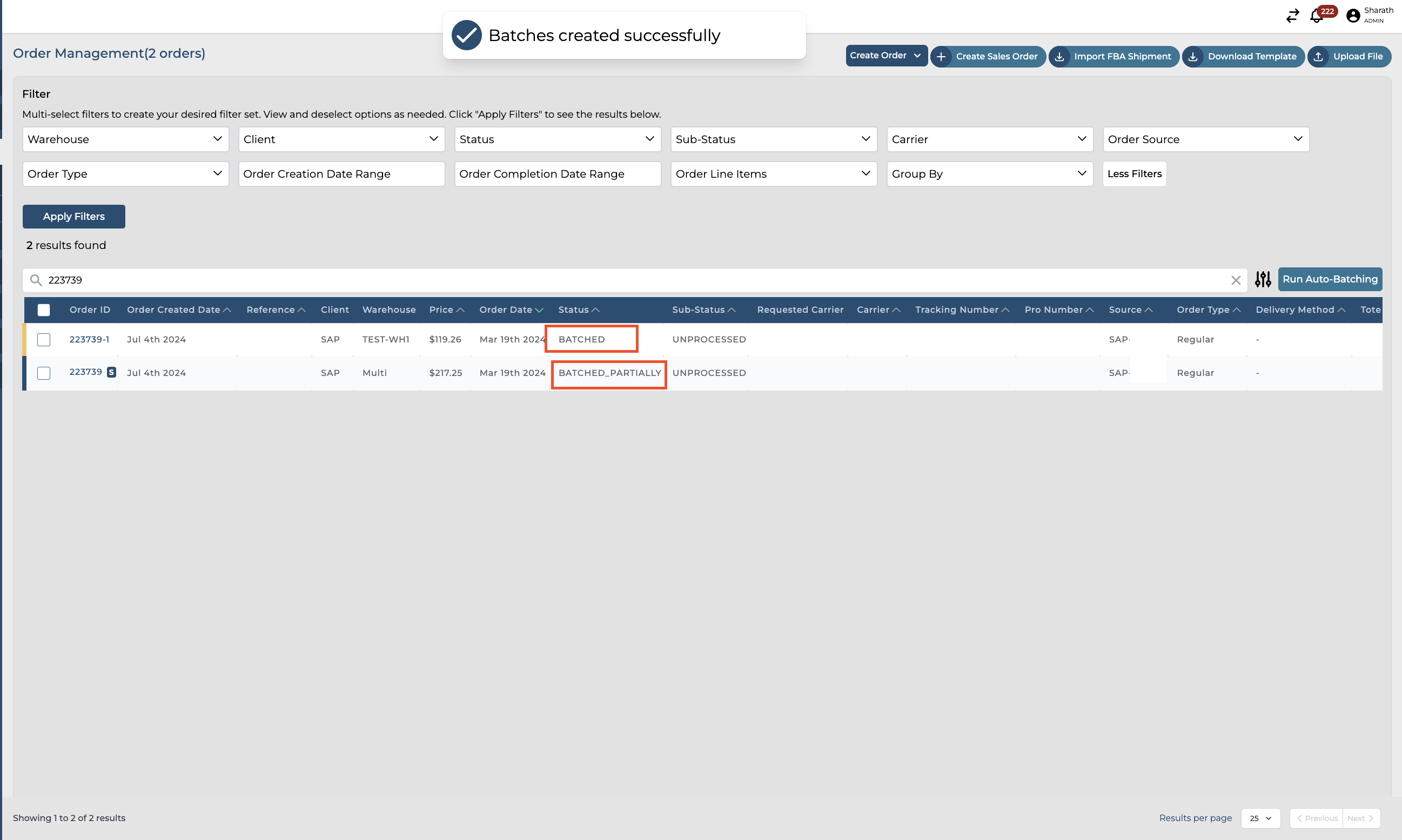

The procedure to batch the order remains the same. In our example, the first child order is batched using the create manual batch option.

When the child order is batched, the status of the batched child order becomes “BATCHED” to indicate that the order has been batched and the status of the parent order becomes “BATCHED_PARTIALLY”.

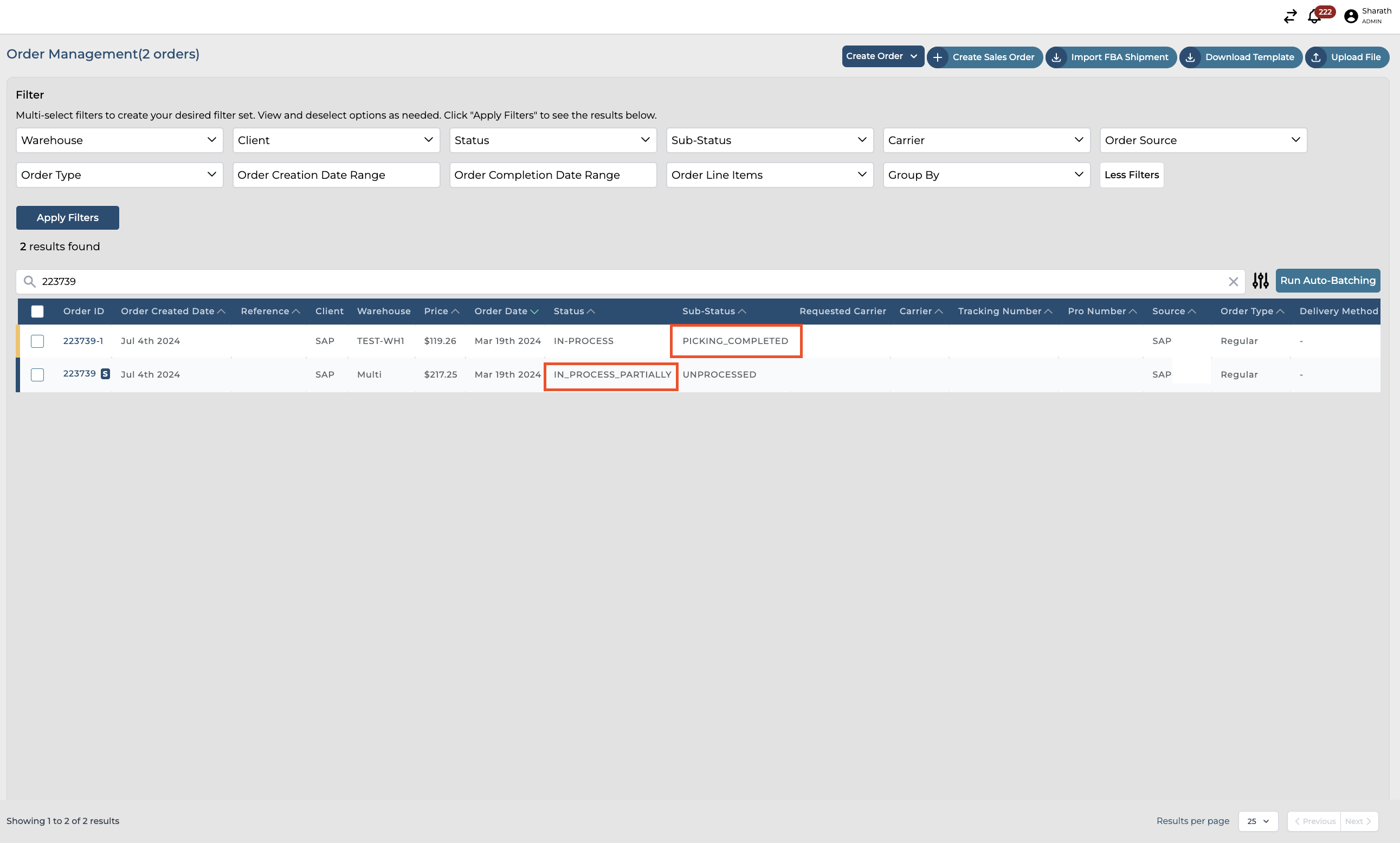

Regular procedures can be followed for picking and packing the order. When the picking is completed for the first child order that was batched, the status of the parent order becomes “IN_PROCESS_PARTIALLY”.

When the packing is completed for the first child order that was batched, the status of the parent order becomes “COMPLETED_PARTIALLY”.

Now the second child order is batched. Once the second child order is batched, the status of the second child order becomes “BATCHED” to indicate that the order has been batched and the status of the parent order reverts back to “BATCHED_PARTIALLY” indicating that one of the child batches has been batched.

Regular procedures can be followed for picking and packing the order. Once the pick and pack for all the child orders are completed the status of the parent order becomes “COMPLETED”.

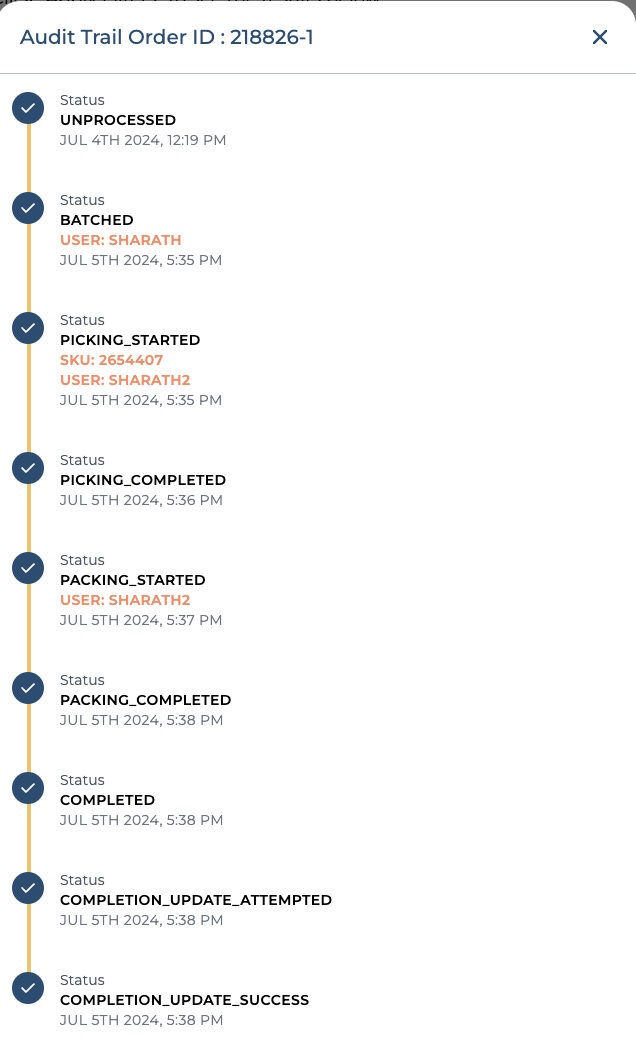

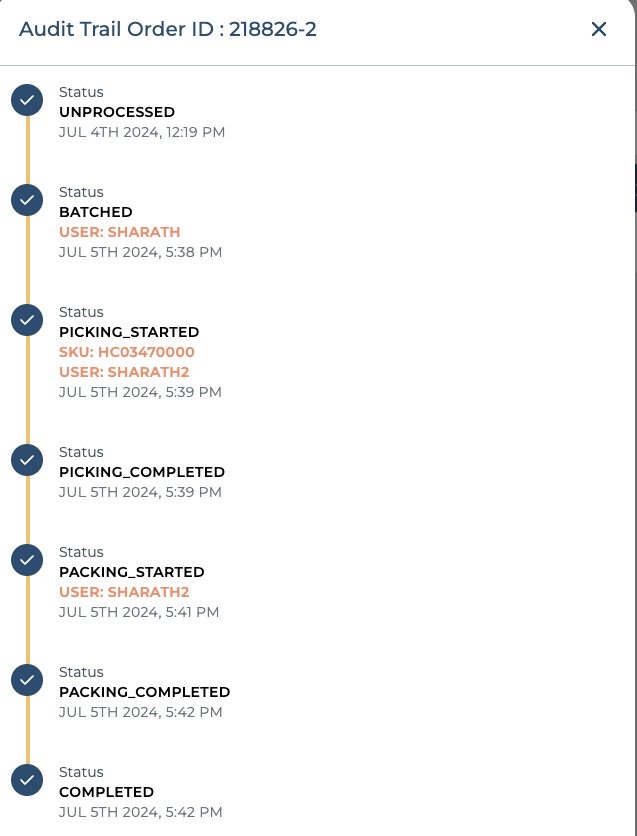

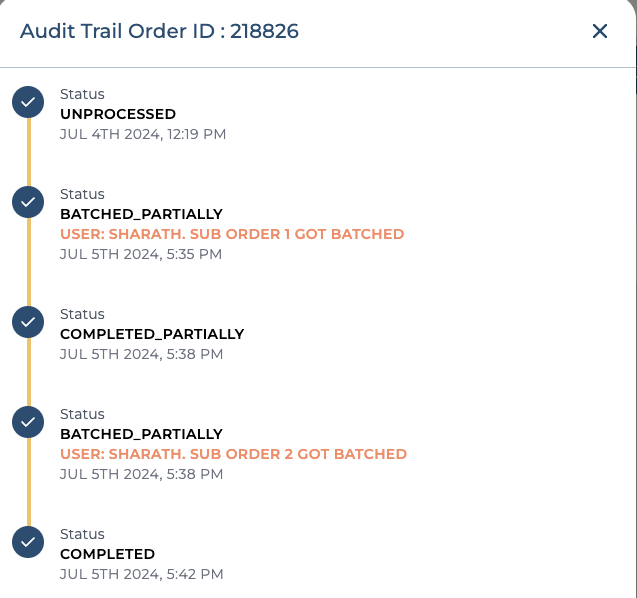

The audit trail provides documentary evidence of sequences of activities and status changes.

Audit Trail of Child Order 1: 218826-1

Audit trail of Child Order 2:

Audit trail of Parent Order

Back Orders in Split Orders

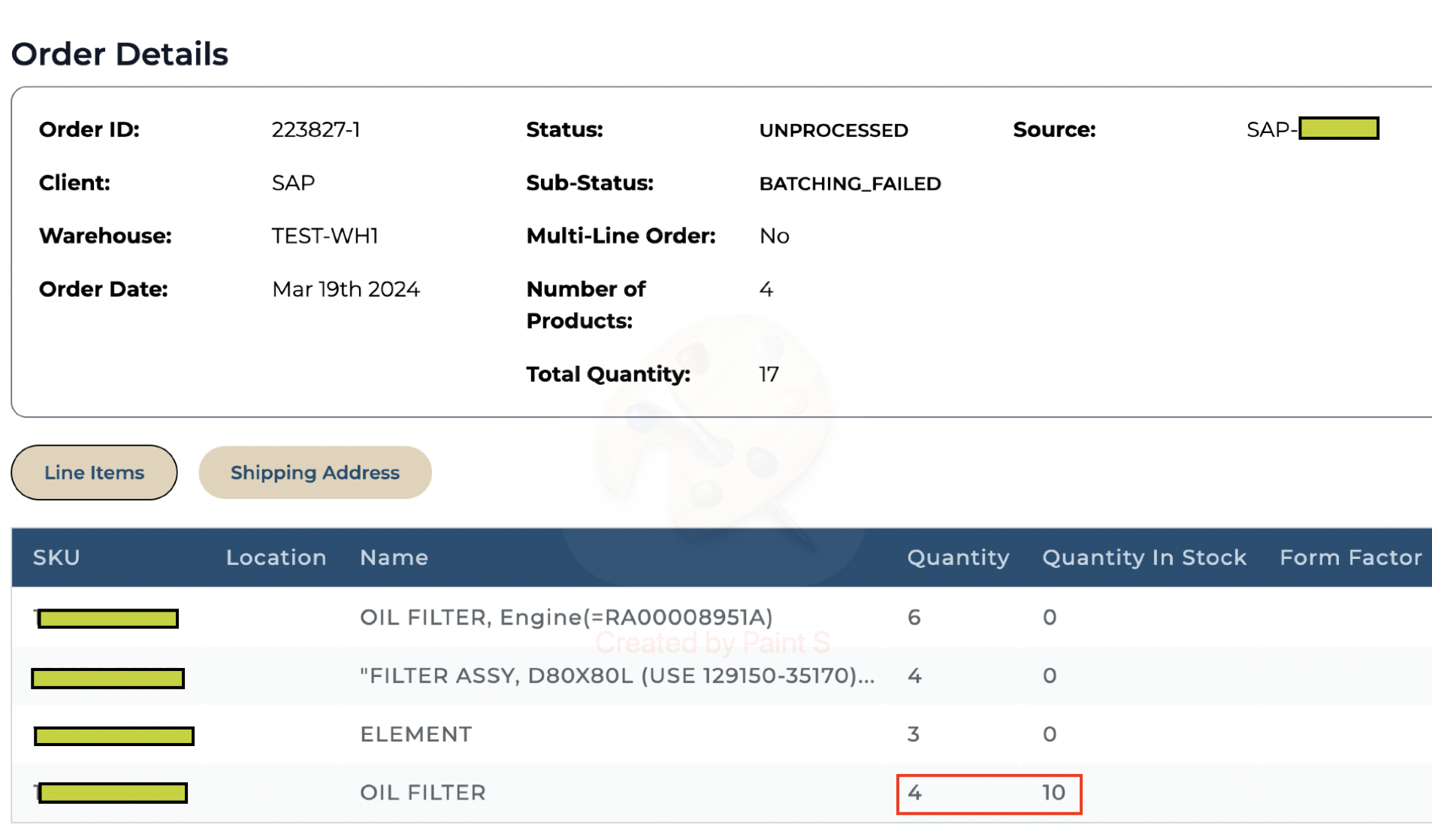

With the improved split orders feature, users will be able to perform partial fulfilment for split orders. When a child order of a split order contains unfulfillable items, the system automatically creates a backorder for any unfulfillable quantity when batched manually. This creates two suborders in the child orders where one suborder is fulfillable allowing fulfilment of the available items, and the other suborder contains remaining items. The child order is recorded as a back order which can be tracked and fulfilled when inventory becomes available.

The screenshot below is an example of a partially fulfillable child order.

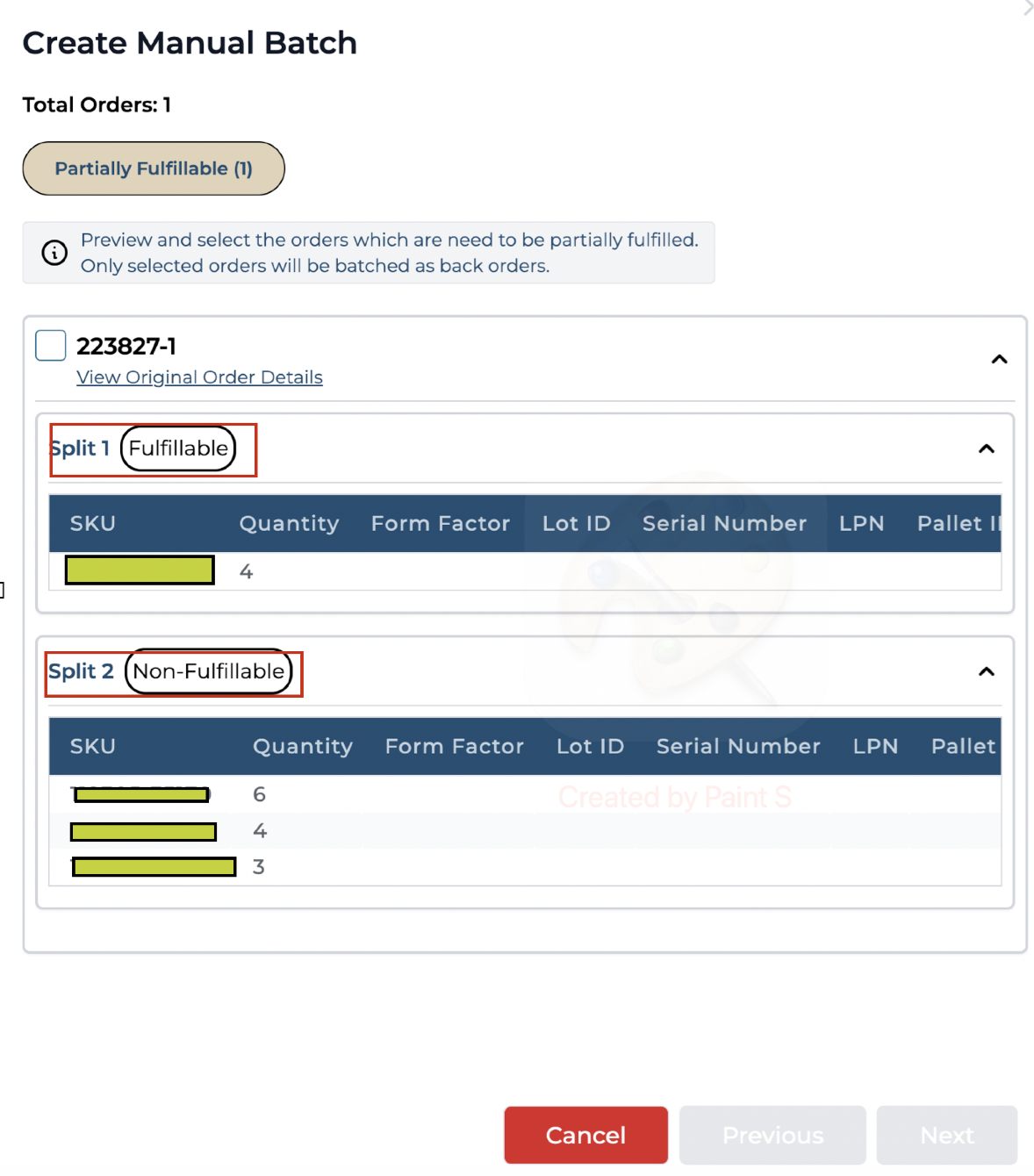

Click on the order and choose Create Manual Batch.

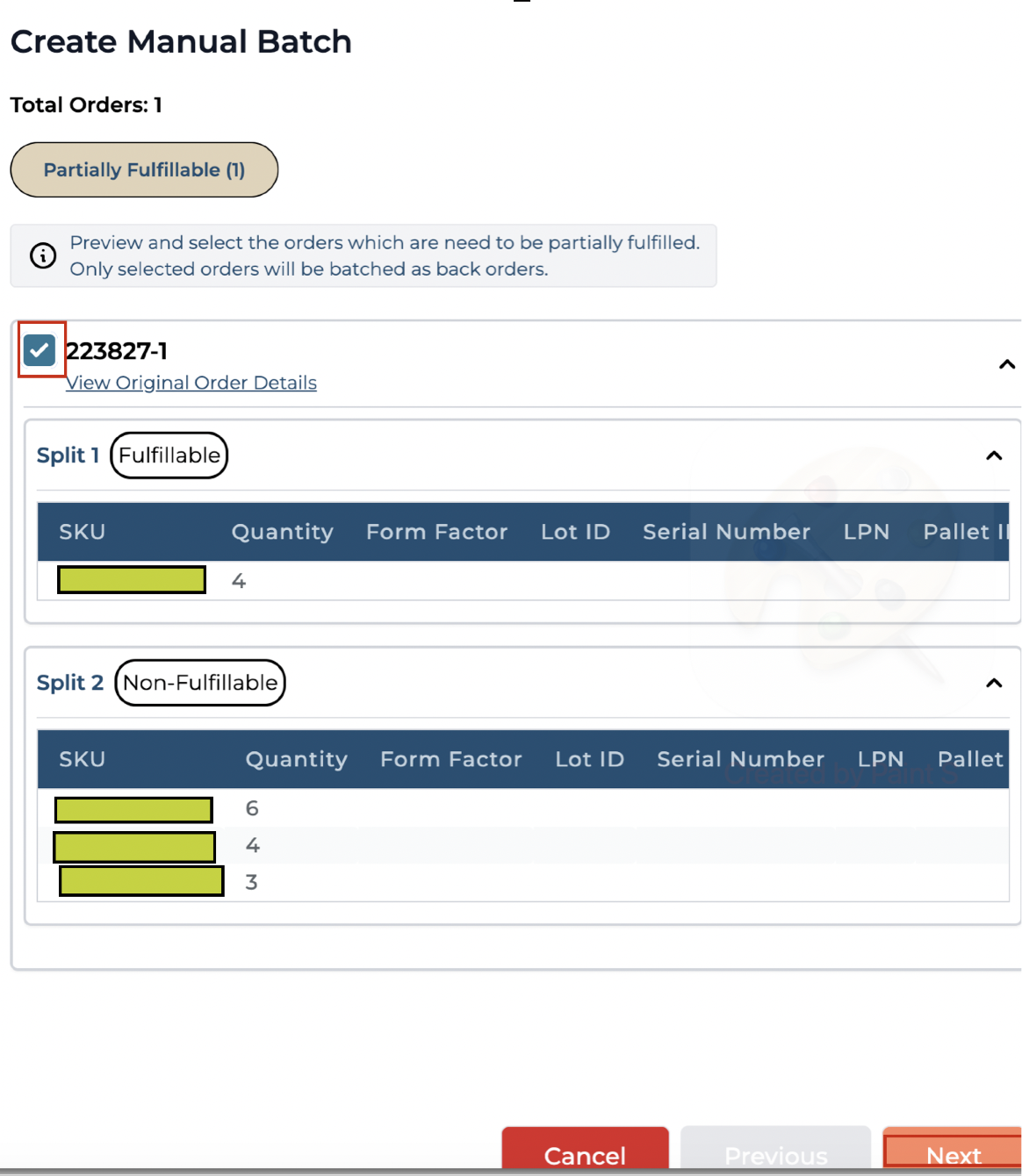

Click on the check box and on next to proceed with batching.

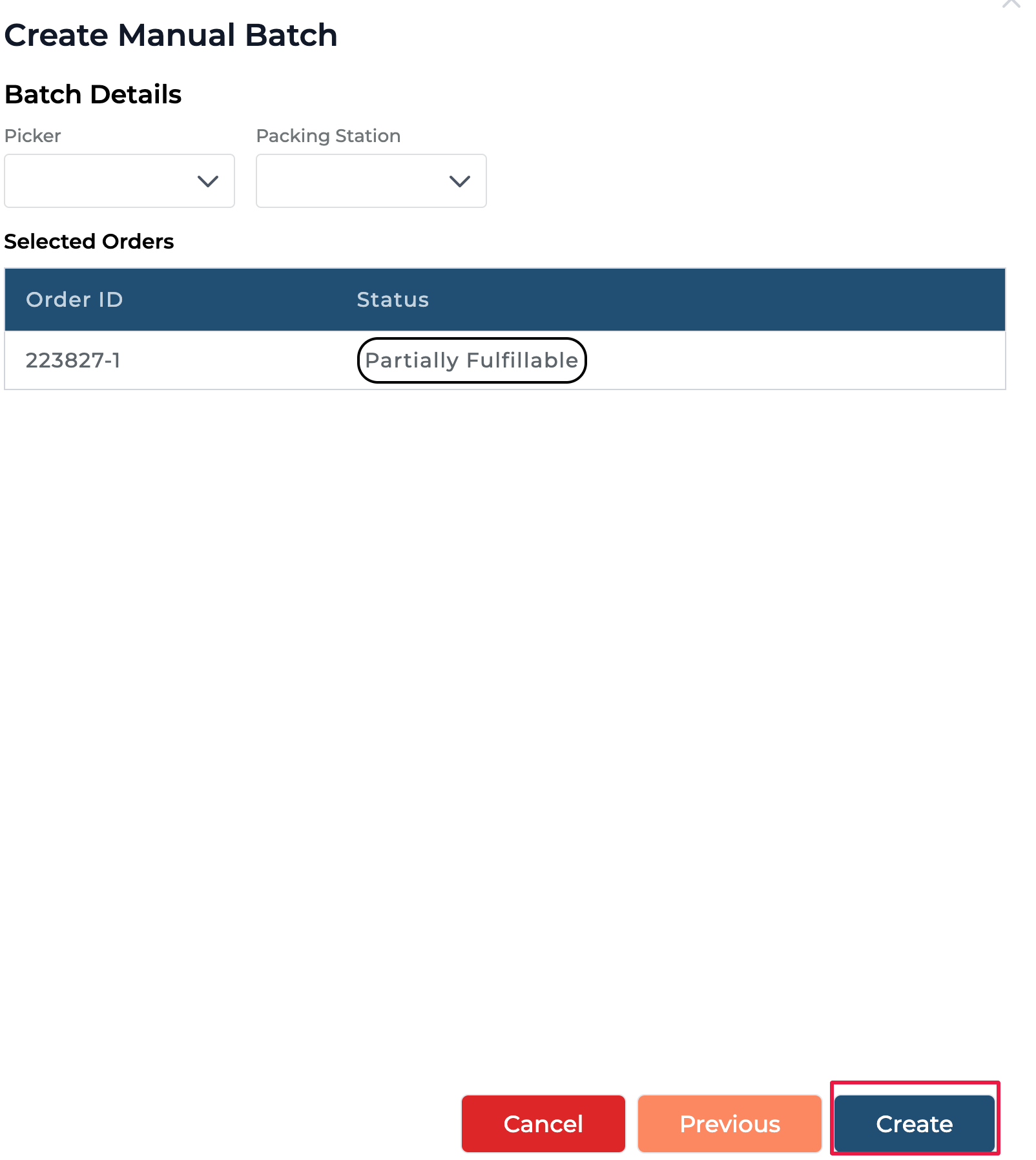

Click on the Create button to complete batching.

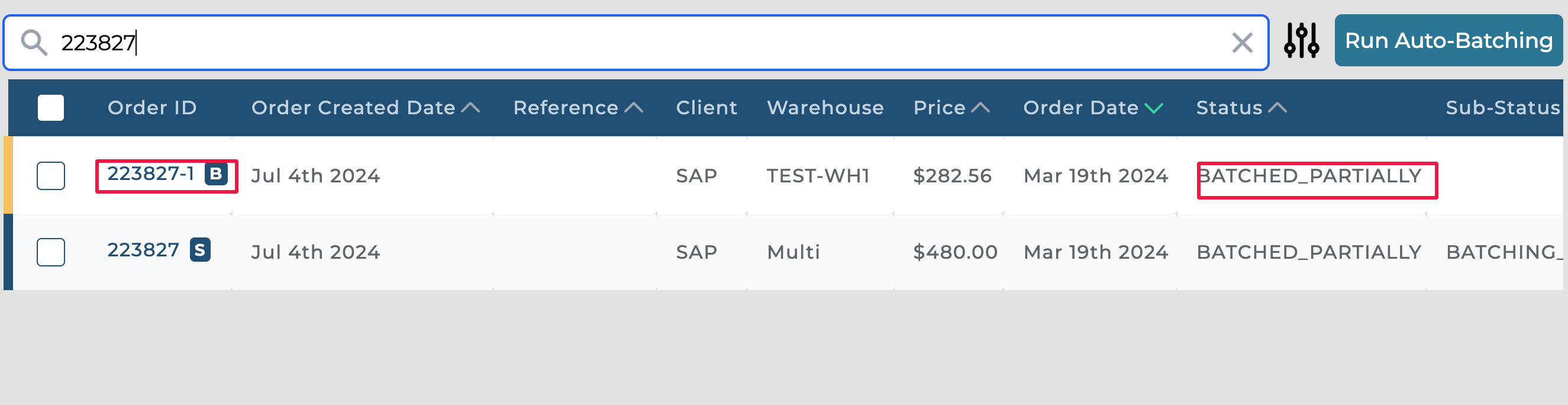

Once the batching is complete the child order gets updated with the letter “B” to denote backorder and the status gets updated to BATCHED_PARTIALLY.

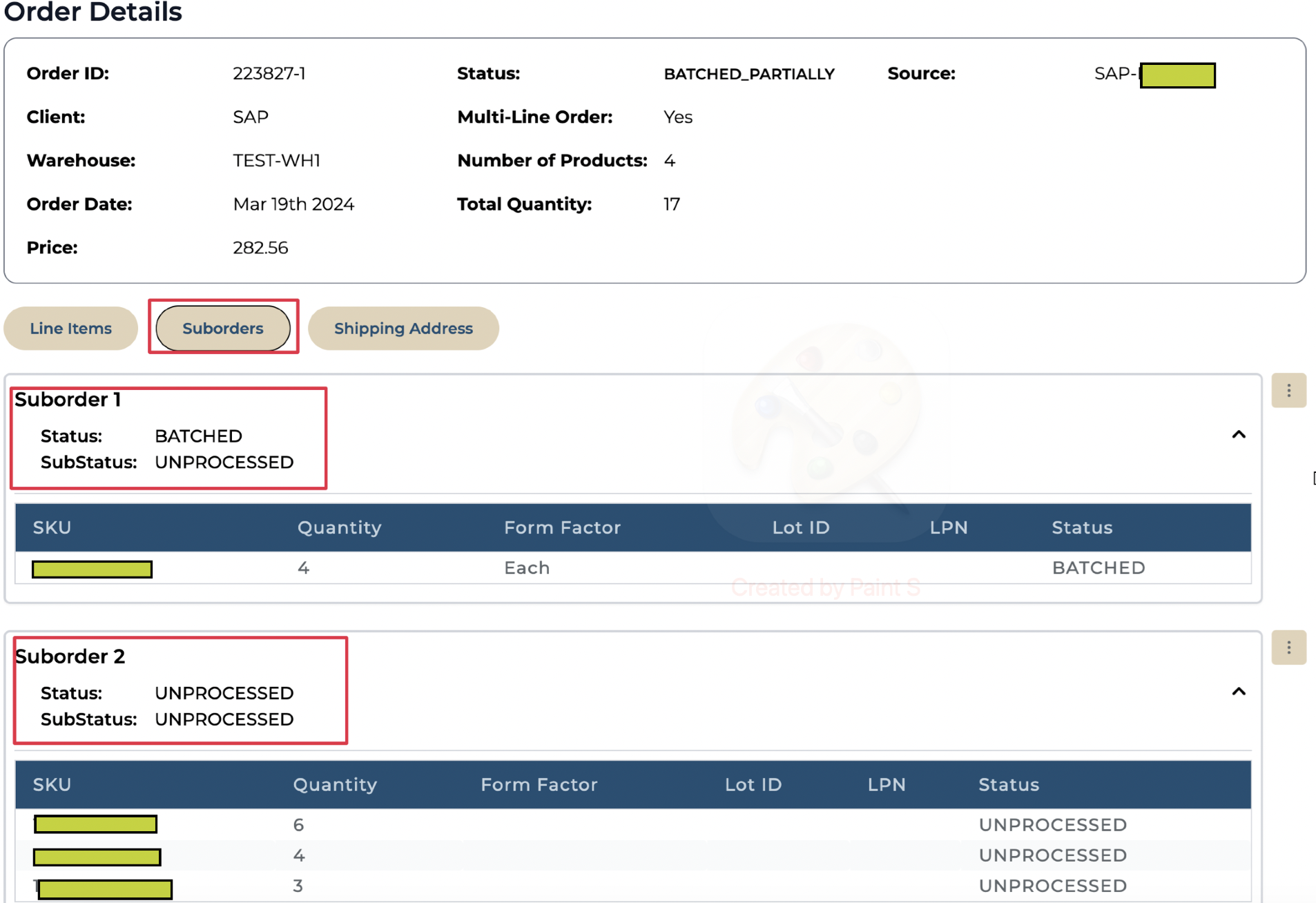

The user can click on the order and navigate to the Suborders tab to view the details of the suborders.

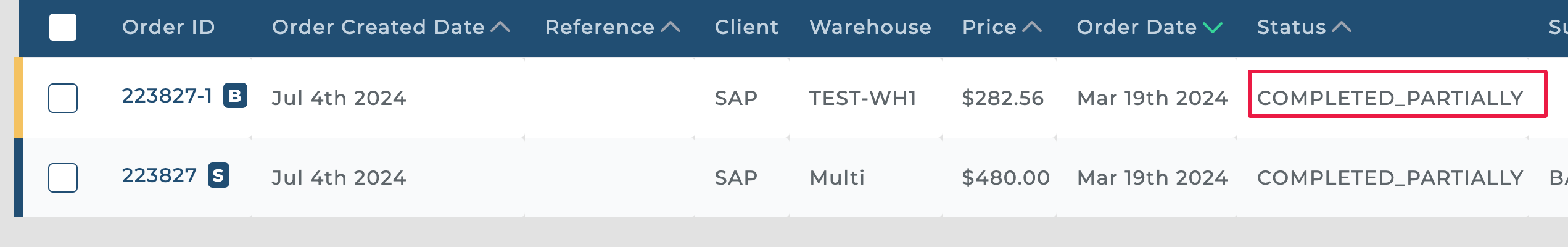

The user can now proceed with the regular procedures for picking and packing for Suborder 1. After completion of picking and packing for Suborder 1, the status of the child order gets updated to “COMPLETED_PARTIALLY”.

The user will have the ability to batch and perform fulfilment for the remaining items in the back-ordered child order when the inventory becomes available.