Picking with Inventory Tracker Scan

We’ve enhanced the picking workflow with a new feature that enables scanning of Inventory Trackers using License Plate Numbers (LPNs) while picking. The system also provides a suggested pick plan based on the units required to be picked and the inventory units and form factors available in the pick location. By allowing pickers to scan and track inventory, this feature significantly boosts inventory accuracy and real-time visibility.

Step 1: Navigate to the picker associate screen and click on Get New Batch.

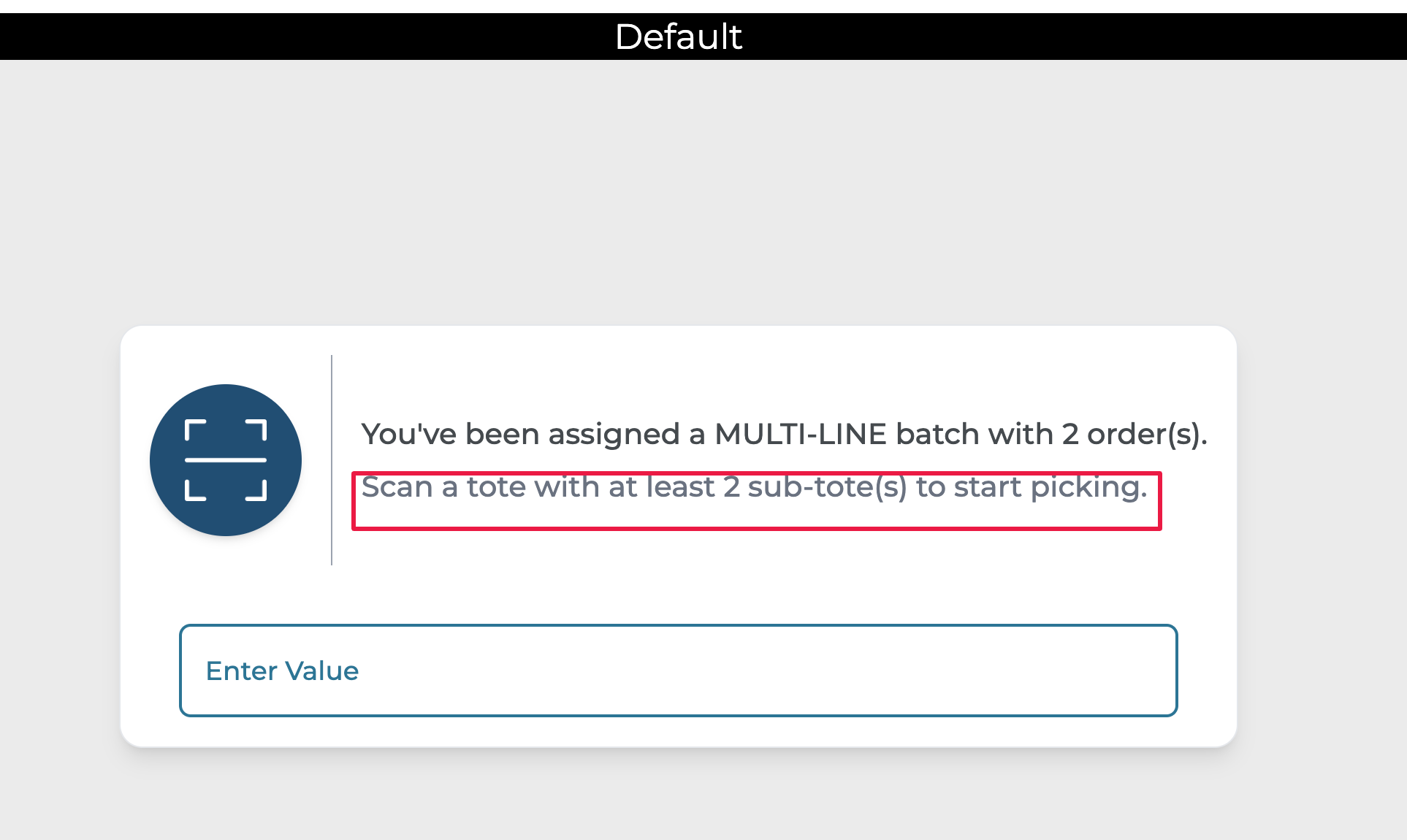

Step 2: Scan Tote

The system guides the user to scan a tote with the right capacity. In the case of a multi-order batch, the system guides the user to scan at tote with a respective number of subtotes based on the number of orders in the picking batch.

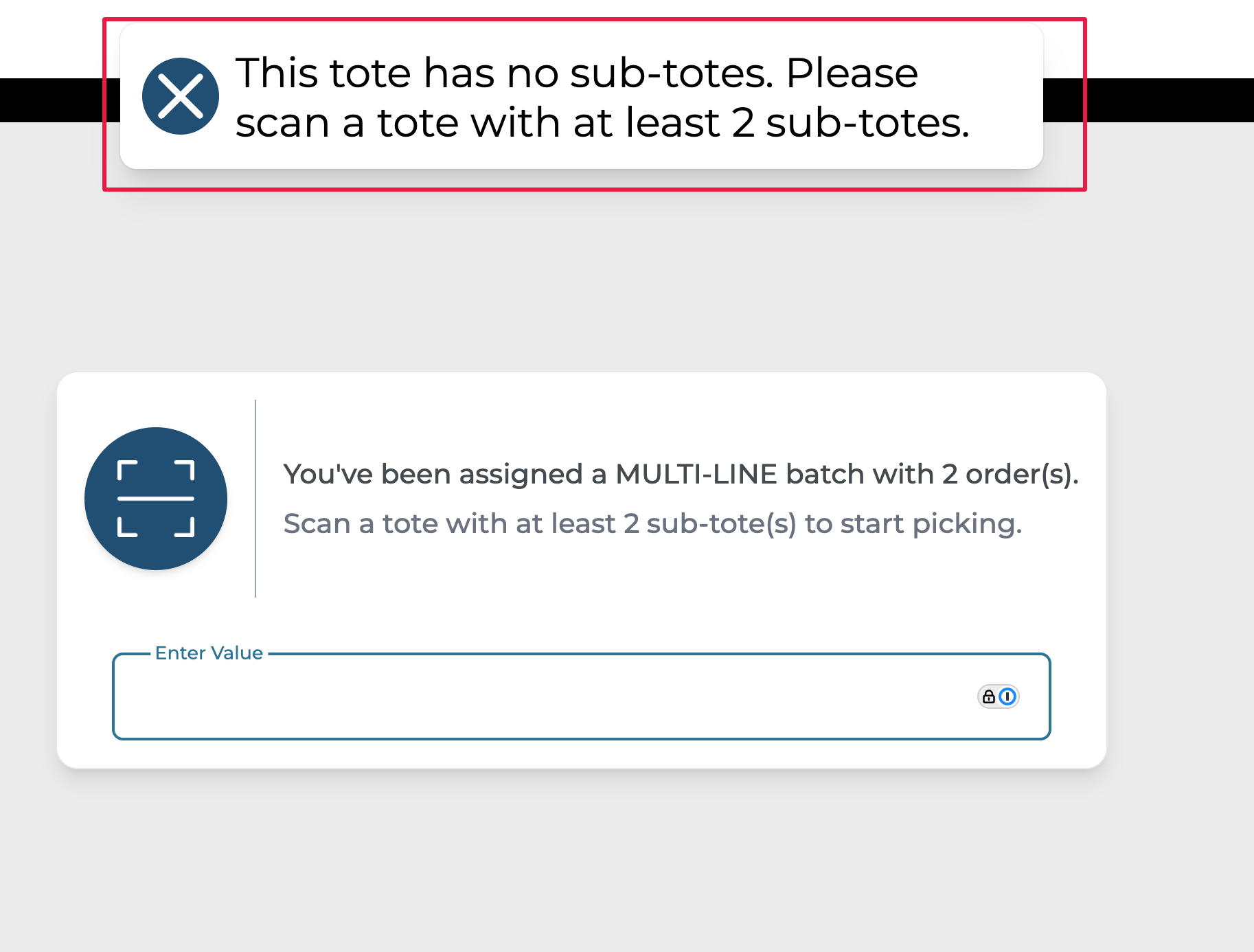

If the scanned tote does not match the requirement, the system throws an error.

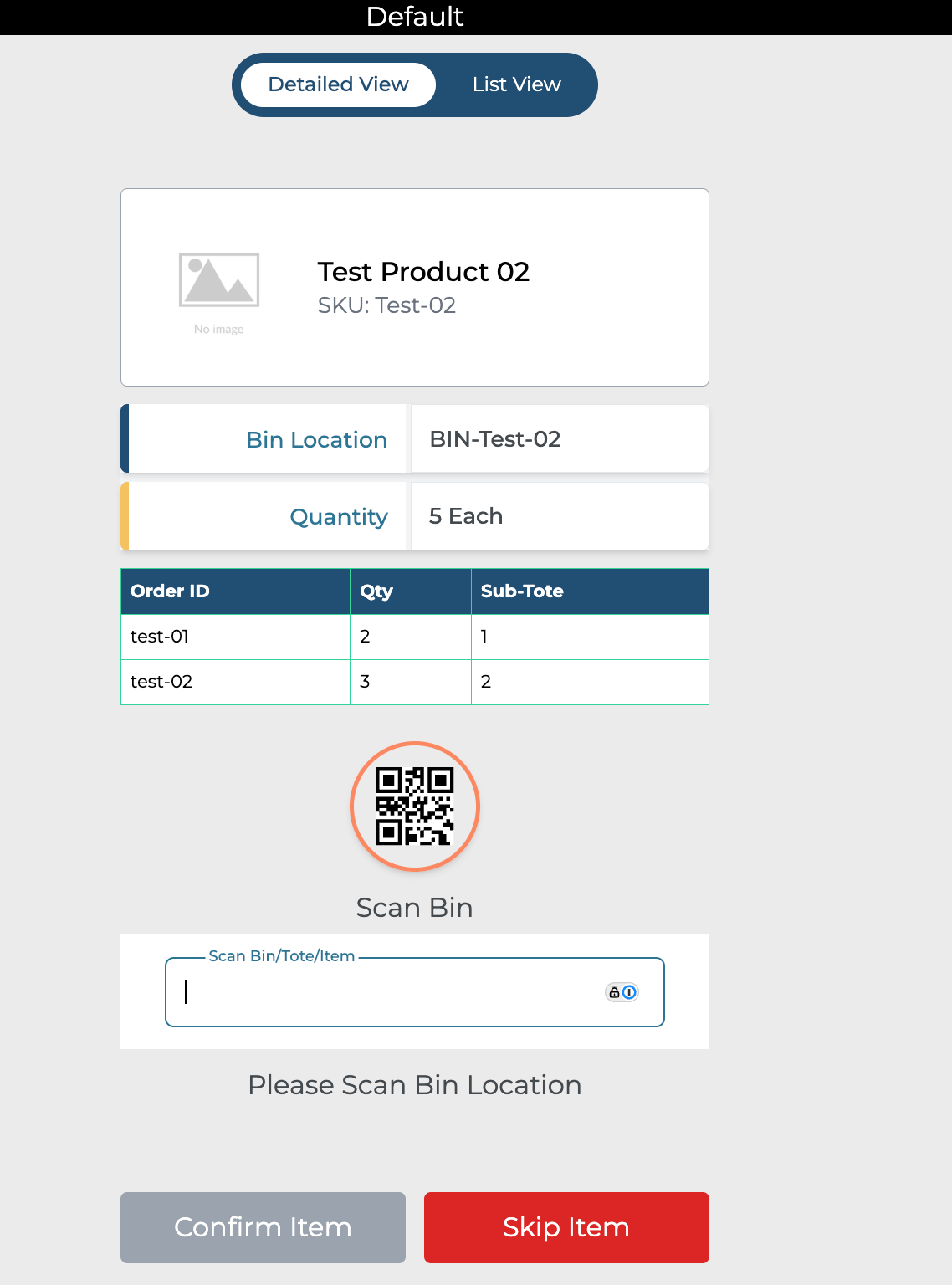

Step 4: Scan Location

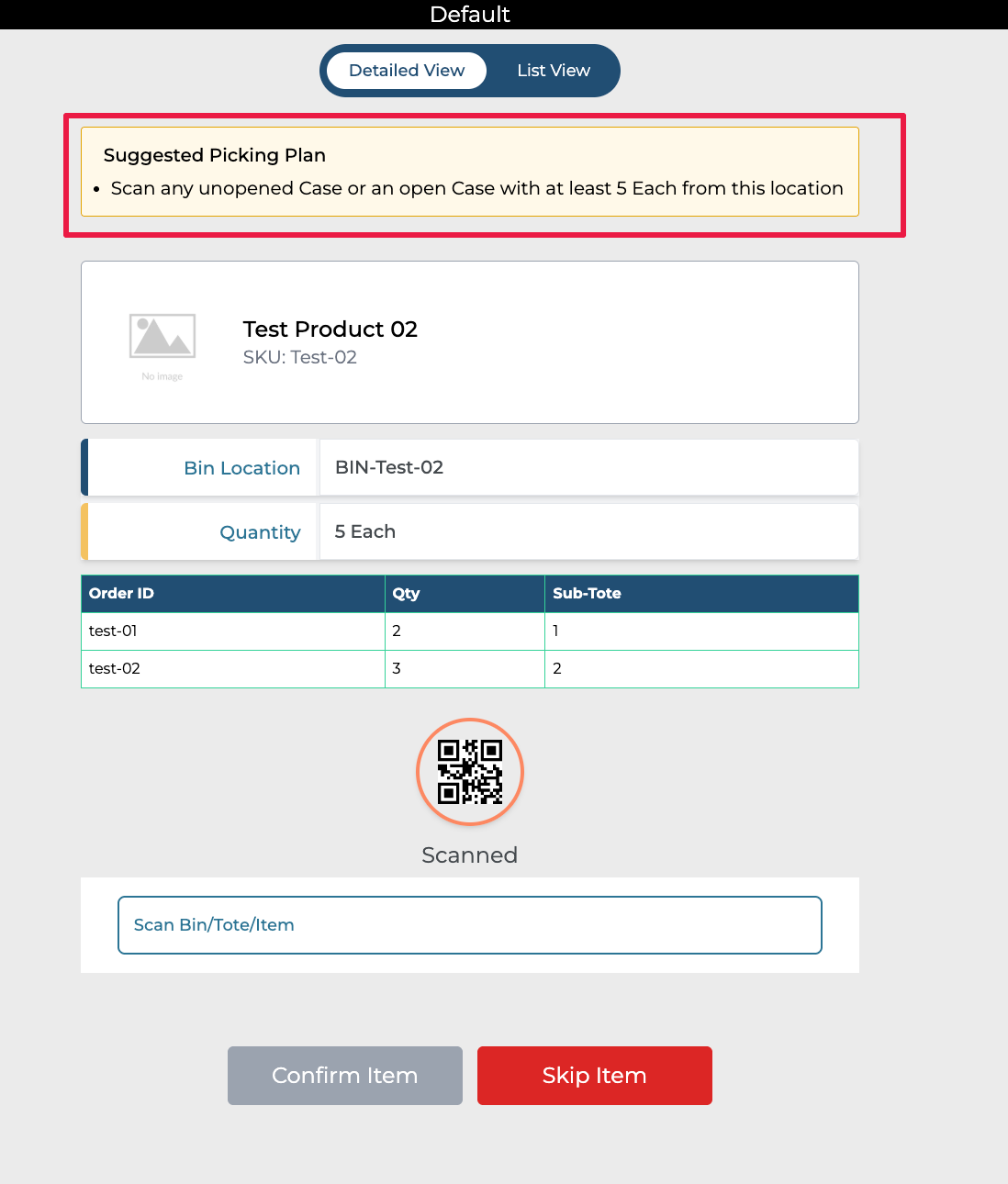

Step 5: The Suggested pick plan appears

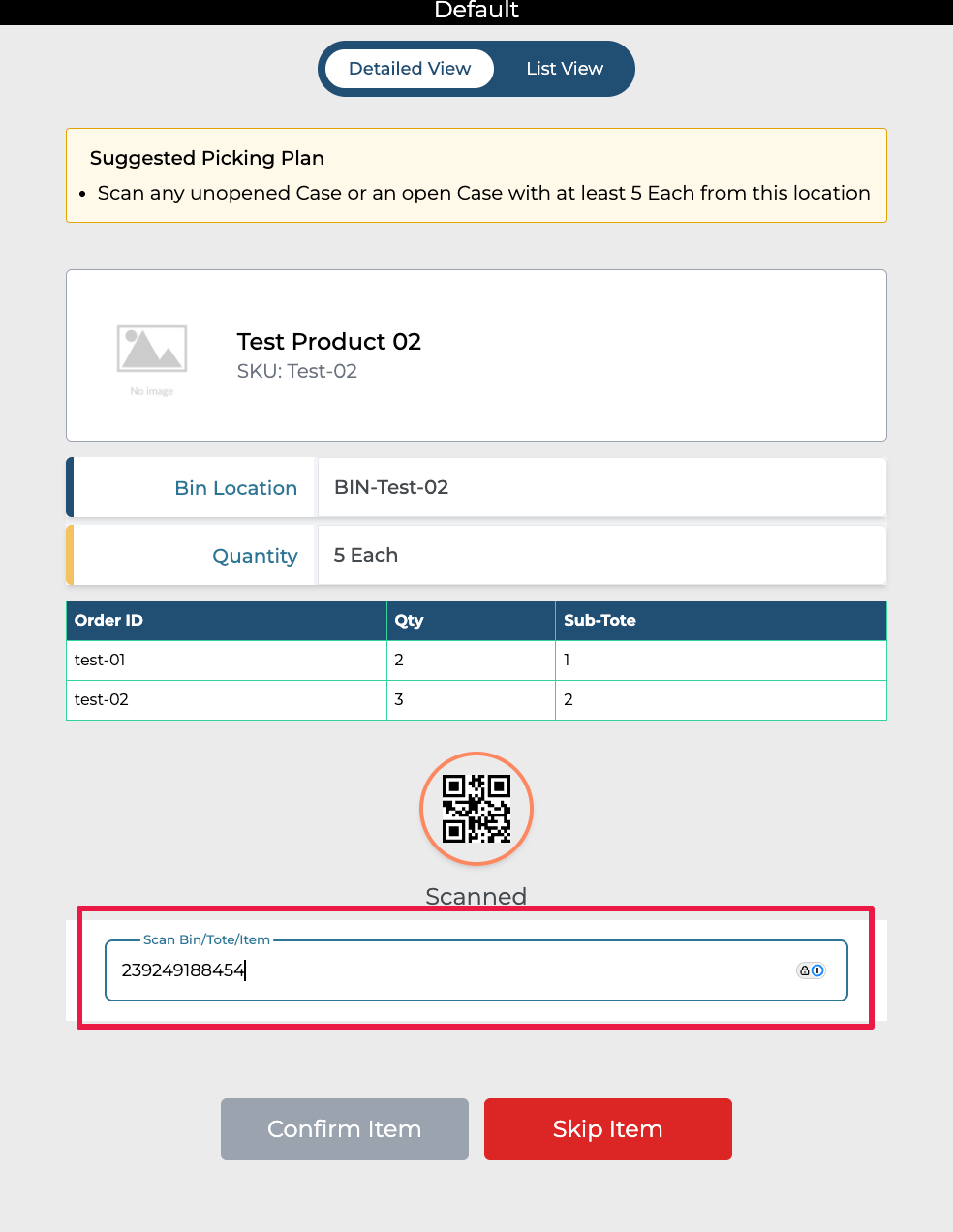

Step 6: Scan LPN

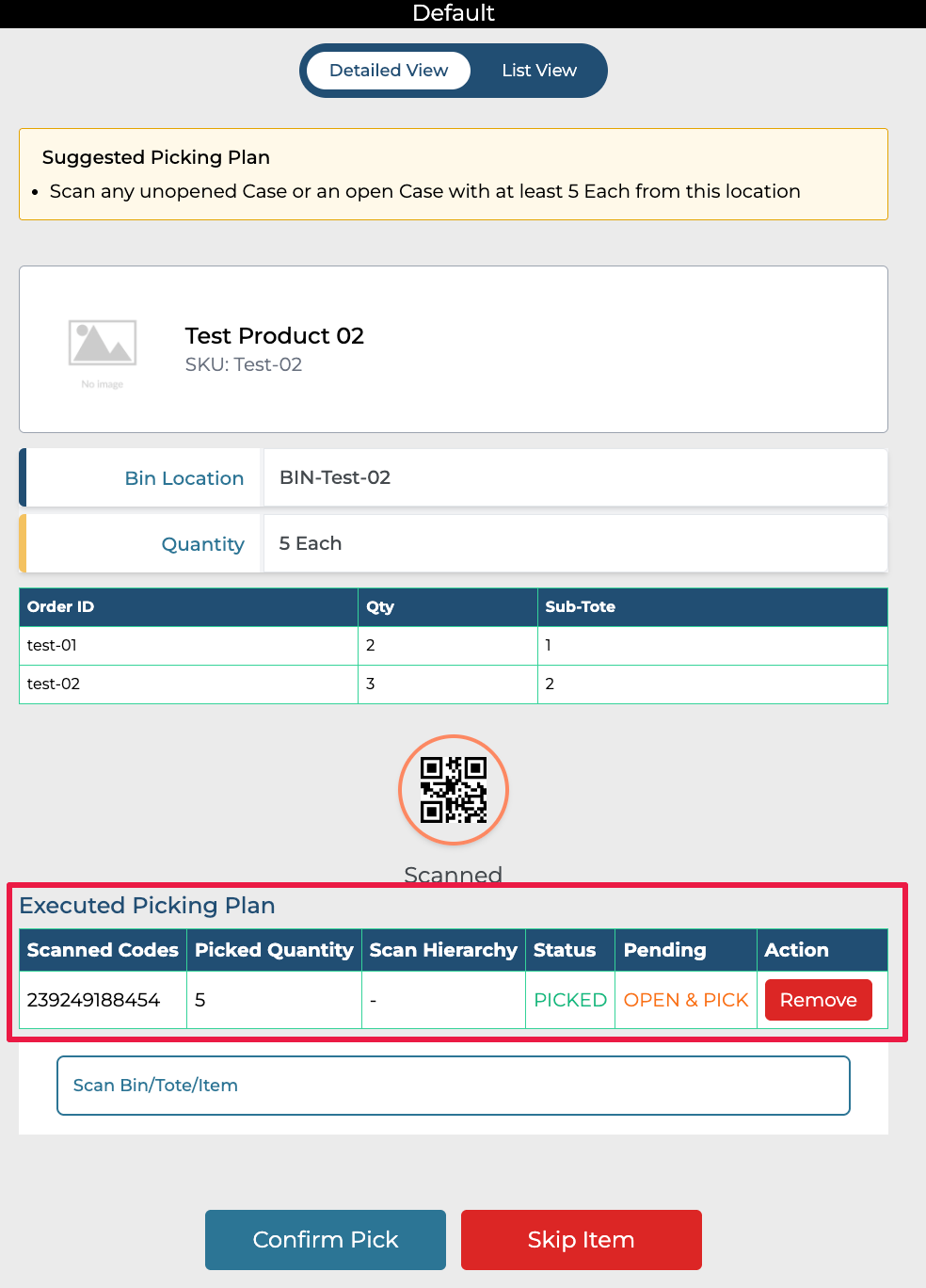

Step 7: The user can see the picking plan execution containing

scanned code - Inventory tracking ID

Picked quantity - Quantity picked

Scan hierarchy - If the units within the Parent Inventory tracking ID have individual tracking IDs that were scanned, that will be displayed here.

Status - shows the status of Picking

Pending - Shows the instruction for picking

Action - The user has the option to remove the picked items by clicking on remove.

Click on Confitm Pick after verifying the executed picking plan.

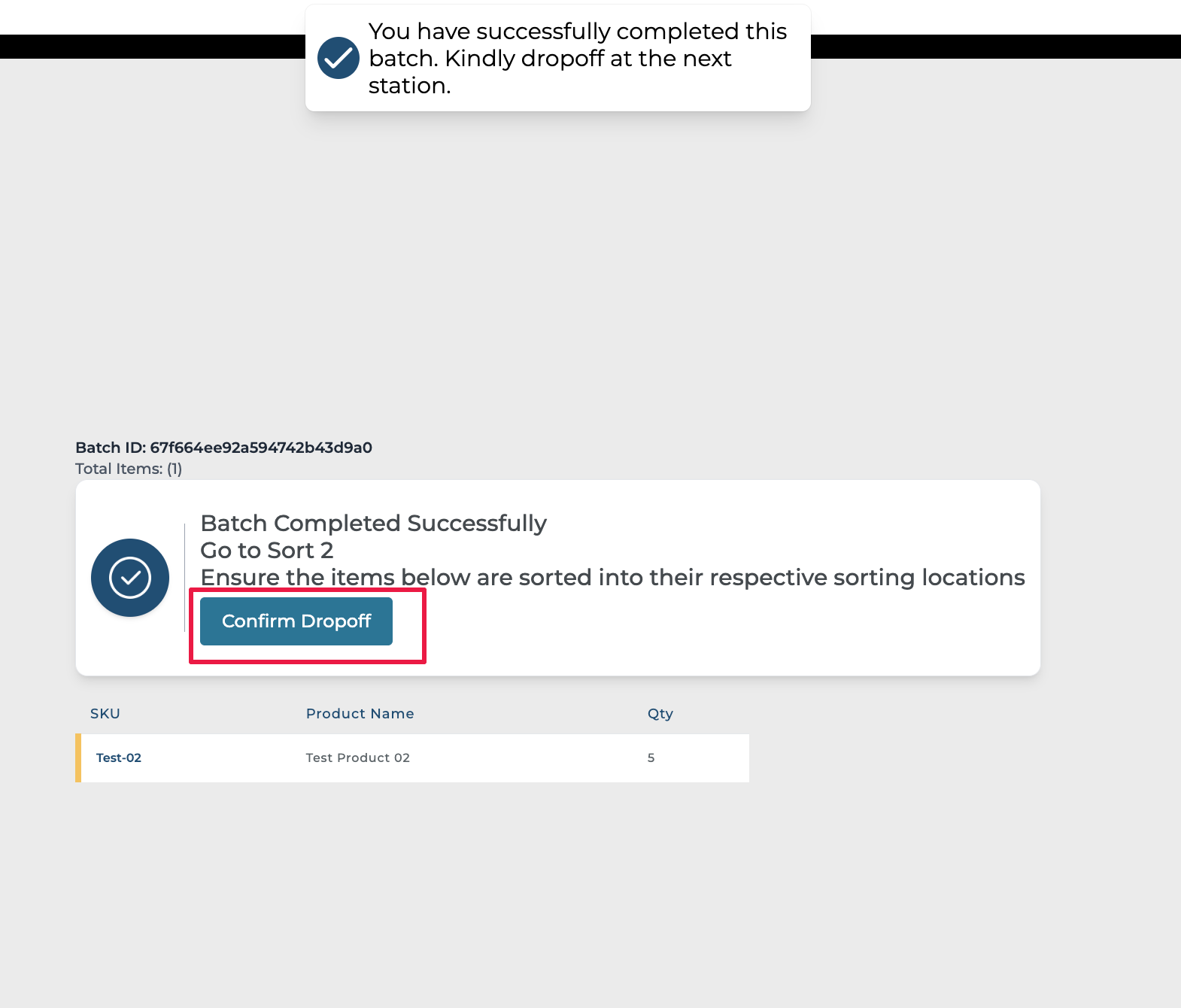

Step 8: Click on Confirm Dropoff to complete picking.

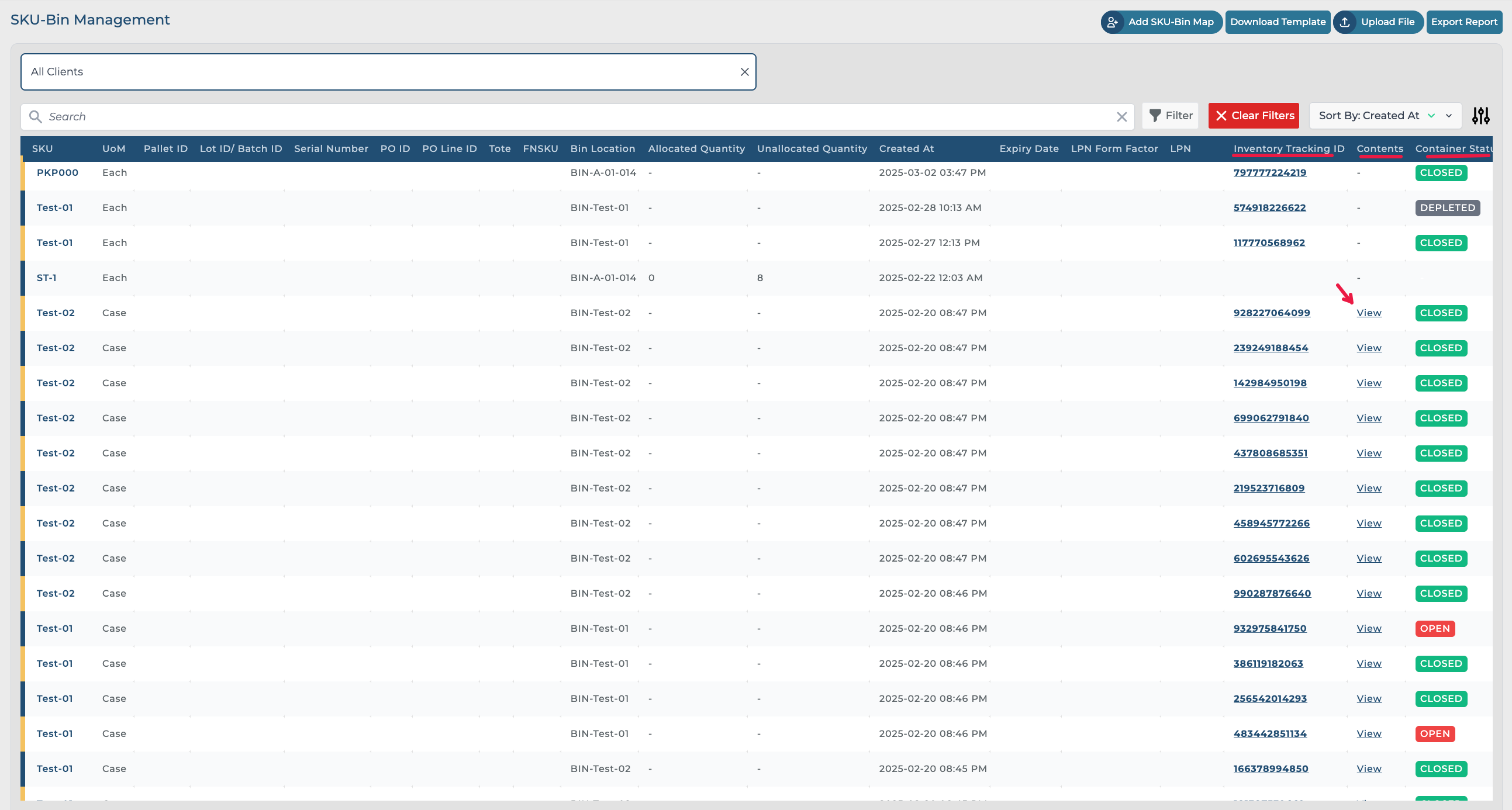

Inventory Tracking linkage in SKU-BIN Mapping:

With this feature, we can see that the SKU-BIN mapping captures the inventory tracking ID along with the container status (Closed, Open, depleted) and the ability to view contents.

This is a gated feature, please reach out to your implementation lead or sales liaison to know more about this.