Instant Bin to Bin Transfer - Picking Workflow

Overview

This workflow enables pickers to instantly transfer inventory between locations when items are discovered at an unexpected location. It helps correct real-world inventory discrepancies without interrupting the ongoing picking process.

Problem Statement

Inventory discrepancies occur when a product is physically located in a different bin/location than what is recorded in the Hopstack platform under SKU Bin Management.

To address this, Hopstack allows real-time location transfers during the Picking workflow, ensuring seamless fulfillment and improved inventory accuracy.

Workflow Steps

1. Start Picking Workflow

Select the Picking workflow on the device.

Scan the tote to begin.

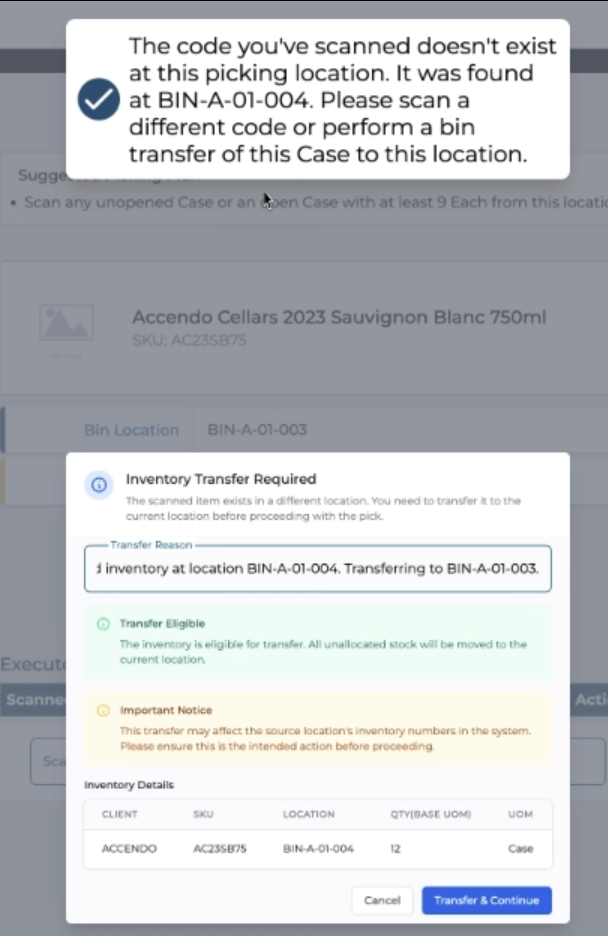

2. Scan Inventory Tracking ID

Scan the Inventory Tracking ID of the SKU to be picked.

If the system detects that the product is in a different location than expected, it will prompt a Location Transfer Required notification.

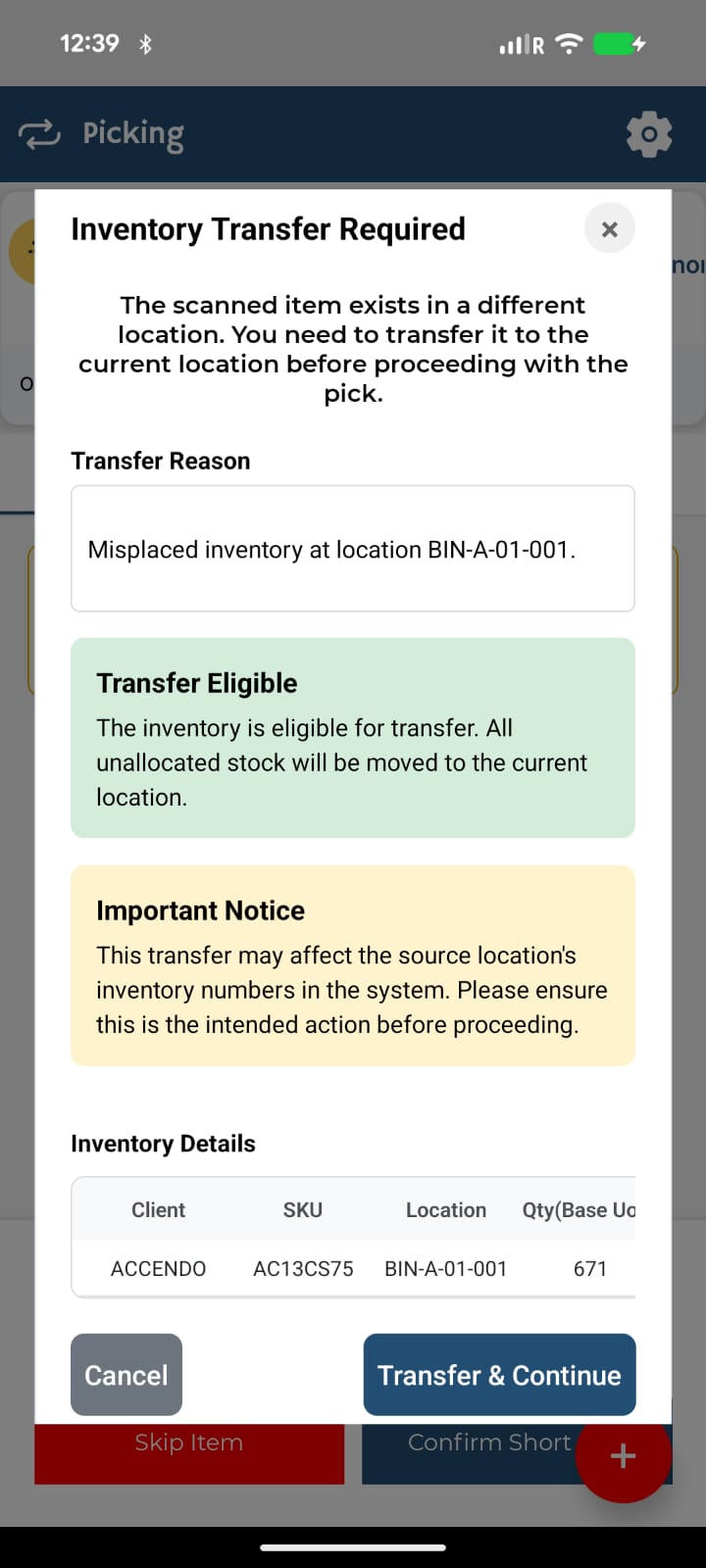

Mobile View:

3. Review Transfer Pop-Up

The system will:

Display the reason for the transfer.

Validate if the transfer is eligible : Inventory transfers are only possible if there is no allocated stock for the SKU at the original location.

Shows inventory details for the SKU.

Note: This transfer may affect the source location inventory number in the system, please ensure this is the intended action before proceeding.

4. Confirm the Transfer

Click Transfer & Continue to proceed.

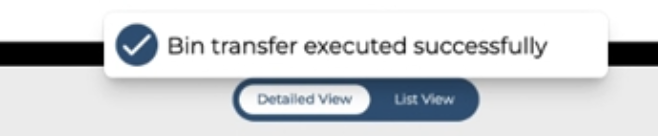

A confirmation notification will be displayed once the transfer is successful.

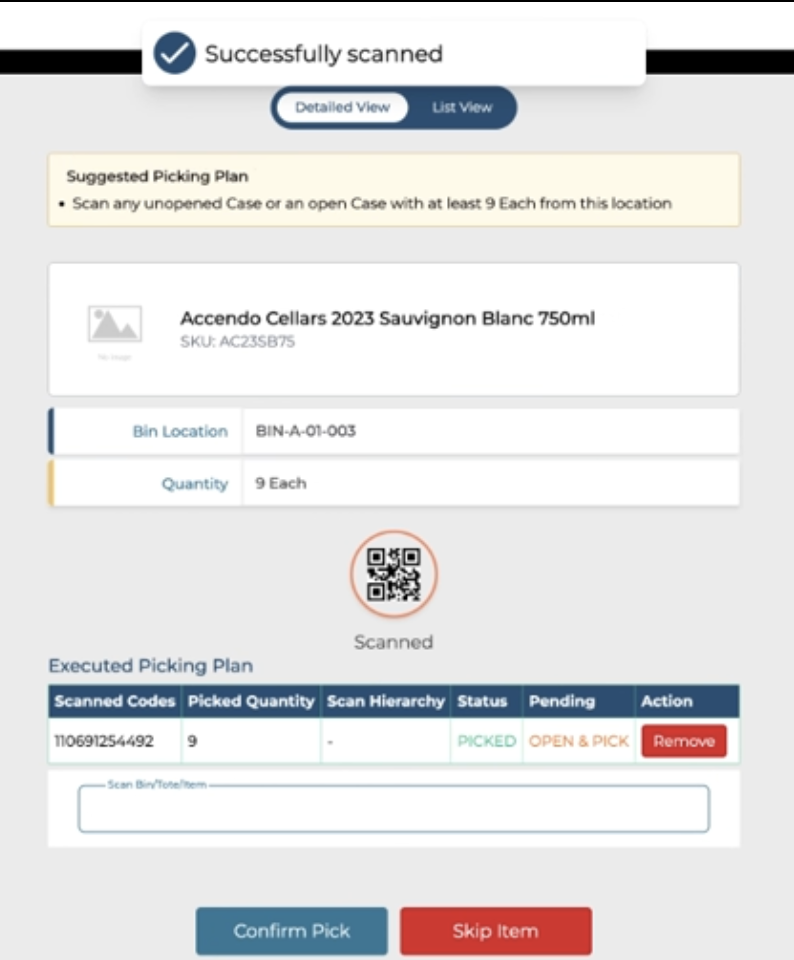

5. Continue Picking

Re-scan the same Inventory Tracking Code.

Click on Confirm Short Pick.

The system will accept the scan as part of the pick and display a Successfully Scanned message.

6. Verify Location Change

Navigate to SKU Bin Management.

Search for the SKU.

The new bin location will now be reflected in the line items.

Limitations

Inventory transfers are only possible if there is no allocated stock for the SKU at the original location.

Key Benefits

Eliminates interruptions in the picking workflow.

Corrects inventory discrepancies in real time.

Improves overall inventory accuracy and visibility.

Reduces delays in order fulfillment.